I searched this forum and a few others on square column mill (ZX45, RF45, PM932, etc.) spindle belt drive conversions but didn't find the specific info I was looking for. Hopefully you all can answer my questions.

First question - why are most conversions ending up with a top speed of around 6,000 rpm? AC and deep groove bearings speed ratings are around 9,000 to 10,000 rpm depending on method of lubrication (oil or grease).

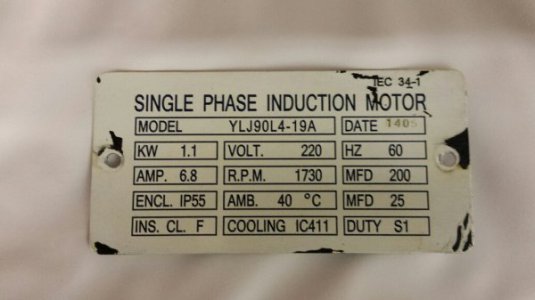

Second question - what are the recommended high and low Hz operating parameters? I've seen numbers as high as 140 Hz but not a lot of information as to why.

Third question - how low of a Hz setting can you run at and still have ample torque with large end mills or face mills?

Fourth question - why two step pulleys, why not three step? Wouldn't that give you a wider rpm range with a narrower Hz band?

TIA,

Tom S.

First question - why are most conversions ending up with a top speed of around 6,000 rpm? AC and deep groove bearings speed ratings are around 9,000 to 10,000 rpm depending on method of lubrication (oil or grease).

Second question - what are the recommended high and low Hz operating parameters? I've seen numbers as high as 140 Hz but not a lot of information as to why.

Third question - how low of a Hz setting can you run at and still have ample torque with large end mills or face mills?

Fourth question - why two step pulleys, why not three step? Wouldn't that give you a wider rpm range with a narrower Hz band?

TIA,

Tom S.