-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speed Using Hss Tools

- Thread starter taycat

- Start date

B

Bill Gruby

Forum Guest

Register Today

Let's start at the beginning.

Why was the HSS recommended and what material are you cutting.

"Billy G"

Why was the HSS recommended and what material are you cutting.

"Billy G"

- Joined

- Dec 3, 2014

- Messages

- 778

Randy why is carbide the same speed for aluminum as HSS in the purple mill chart above..... seems odd to me.

michael

michael

Taycat,

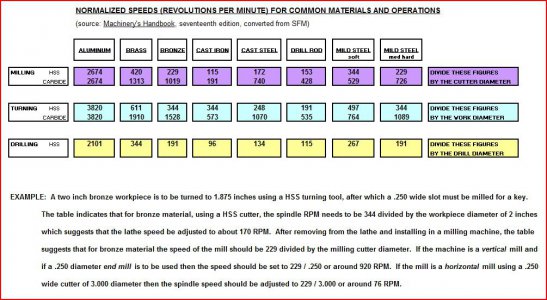

Print yourself out a good chart with 'surface feet per minute' (SFM) or a chart like above for different material and put it next to your machine. I prefer a chart with SFM. Then you can just use the formula to figure what RPM you should use. If you use the chart above, take out the step of multiplying by 3.42.

SFM*3.42/Dia of work piece or for milling SFM*3.42/dia of tool.

But remember this is just a guide line, like mentioned above the RPM could vary because of setup, safety, machine rigidity, ect. So if you had HSS tooling cutting .75" dia mild steel barstock. I would start with 60SFM, so 60*3.42/.75 = 273.6 RPM. I would go to the closest speed your machine has without going over and then adjust from there.

Bryan

Print yourself out a good chart with 'surface feet per minute' (SFM) or a chart like above for different material and put it next to your machine. I prefer a chart with SFM. Then you can just use the formula to figure what RPM you should use. If you use the chart above, take out the step of multiplying by 3.42.

SFM*3.42/Dia of work piece or for milling SFM*3.42/dia of tool.

But remember this is just a guide line, like mentioned above the RPM could vary because of setup, safety, machine rigidity, ect. So if you had HSS tooling cutting .75" dia mild steel barstock. I would start with 60SFM, so 60*3.42/.75 = 273.6 RPM. I would go to the closest speed your machine has without going over and then adjust from there.

Bryan