- Joined

- Dec 30, 2020

- Messages

- 54

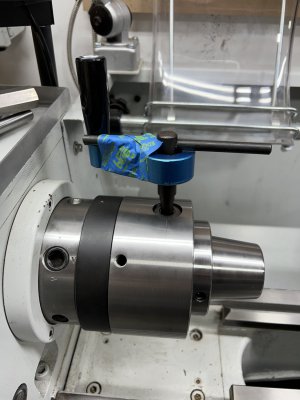

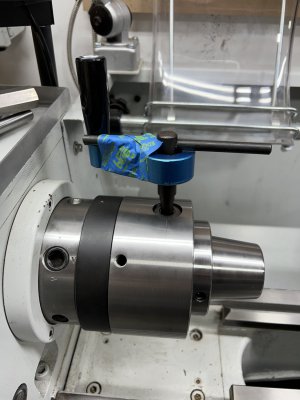

This was my first real multi-machine project. Everything up until this one was either exclusively turning or milling/drilling. I plan to turn a new handle for the tool but for now it works perfectly fine. This was my first time every using a 5c chuck and I was actually surprised by the amount of turns it took to close the collet on the part. The factory T-handle needed to be put out to pasture.

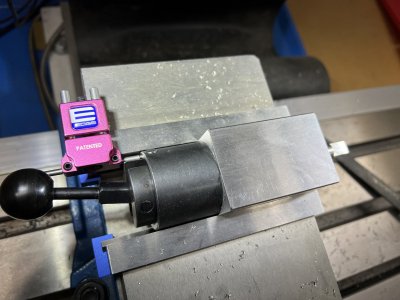

I found this one on amazon that was designed for 6" milling vises. While perfectly suitable for testing clearances for the tool and my knuckles, something was telling me that this rev1 was not going to hold up to shop action...

So instead of using some mystery bar stock I had laying around, I ordered some 3/4" 303 Hex bar from McMaster-Carr to expedite the process a bit.

Cut to rough length:

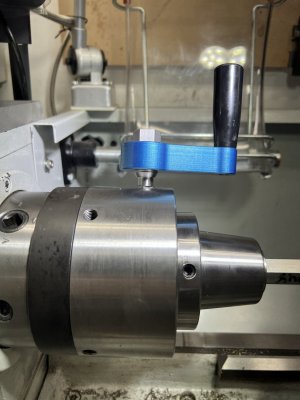

Turned down to final OD of the chuck closer and added a transition to the profile:

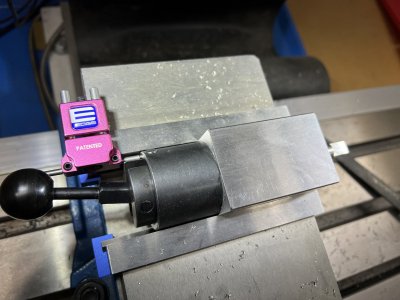

These vise blocks are pretty awesome. I was easily able to index the square collet block precisely for milling each of the four sides of the closer profile:

Switched the part over the Hex block and added a chamfer to the wrench side of the part:

Back into the lathe for a clean up with scotch-brite:

SS Part is finished:

Drilled and tapped for an allen grub screw and this thing is ready for action:

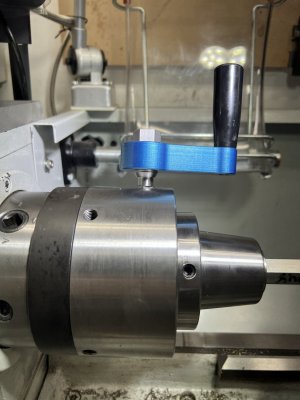

Fit is perfect!

One more thing....

I found this one on amazon that was designed for 6" milling vises. While perfectly suitable for testing clearances for the tool and my knuckles, something was telling me that this rev1 was not going to hold up to shop action...

So instead of using some mystery bar stock I had laying around, I ordered some 3/4" 303 Hex bar from McMaster-Carr to expedite the process a bit.

Cut to rough length:

Turned down to final OD of the chuck closer and added a transition to the profile:

These vise blocks are pretty awesome. I was easily able to index the square collet block precisely for milling each of the four sides of the closer profile:

Switched the part over the Hex block and added a chamfer to the wrench side of the part:

Back into the lathe for a clean up with scotch-brite:

SS Part is finished:

Drilled and tapped for an allen grub screw and this thing is ready for action:

Fit is perfect!

One more thing....

Last edited: