- Joined

- Dec 27, 2019

- Messages

- 18

I thought that I'd share a few things to make my PM1030V lathe more useful. All of these items should work on the PM1022V and some should work on similar type lathes. I watch the same machinist channels that most of you do but these are my interpretations.

Chuck Key Holders

I'm actually very happy with the ways these turns out. Others have shown similar ones but over the years I've moved to open-source tools after being a victim of abandonware and pay-lots-o-money-ware. I do machining for fun, not profit. I create a parametric FreeCAD model for these holders and you simply need to type in the size of the chuck key to get a custom-fitted holder. Then 3D print it! Get the CAD model and everything else here: PM1030V PM1022V Lathe Chuck Key Holders

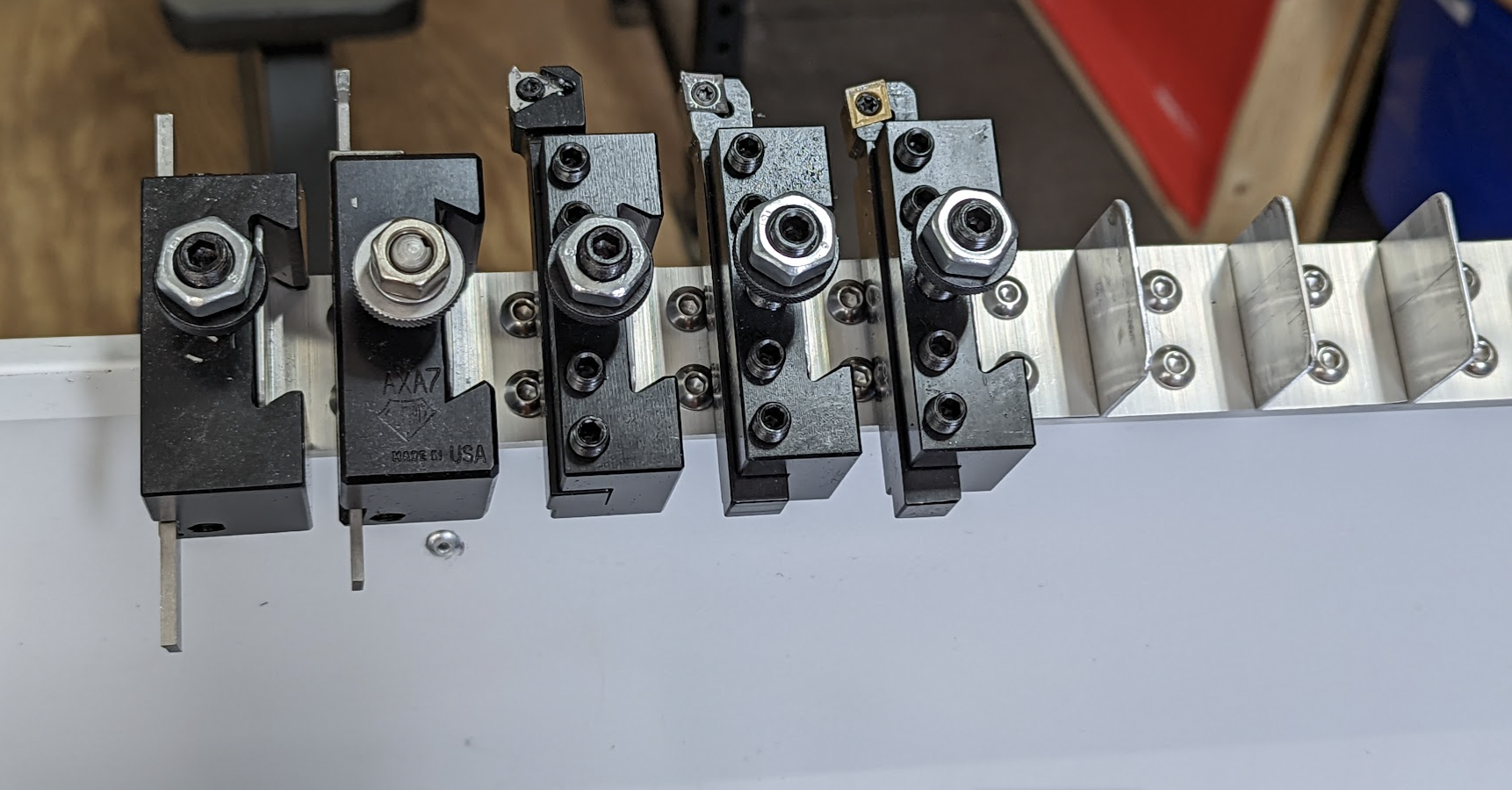

Tool Holder Rack

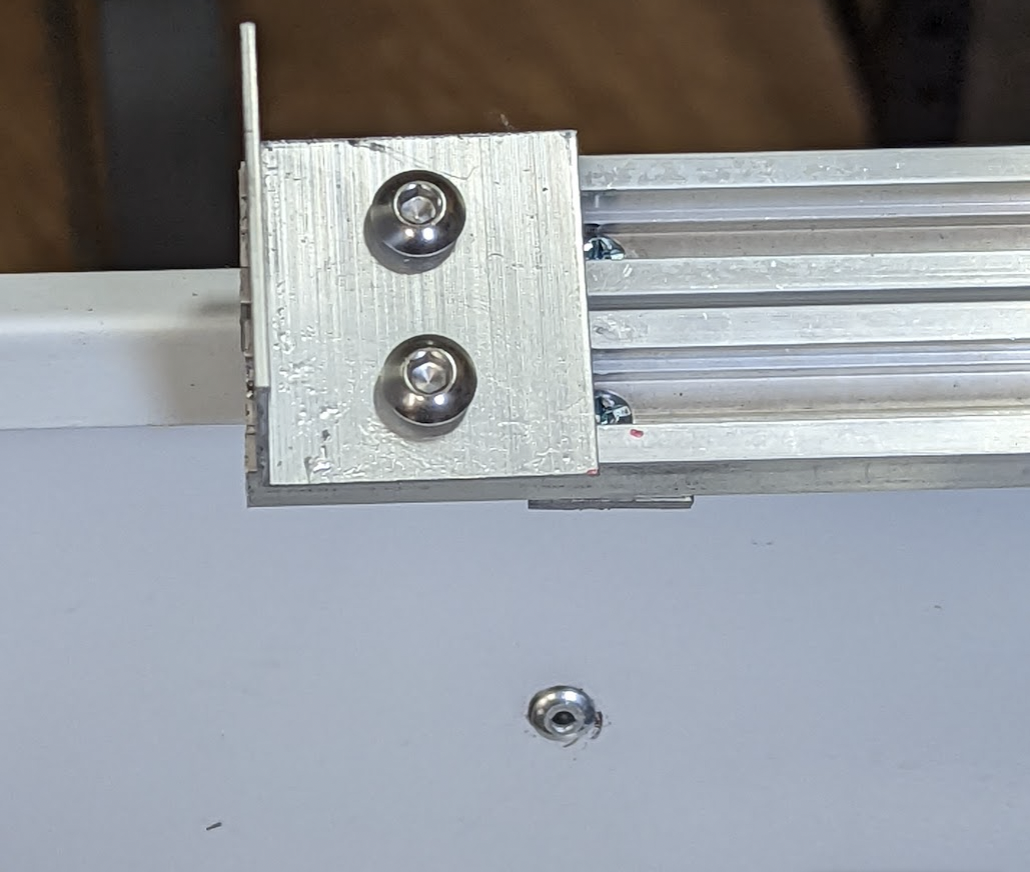

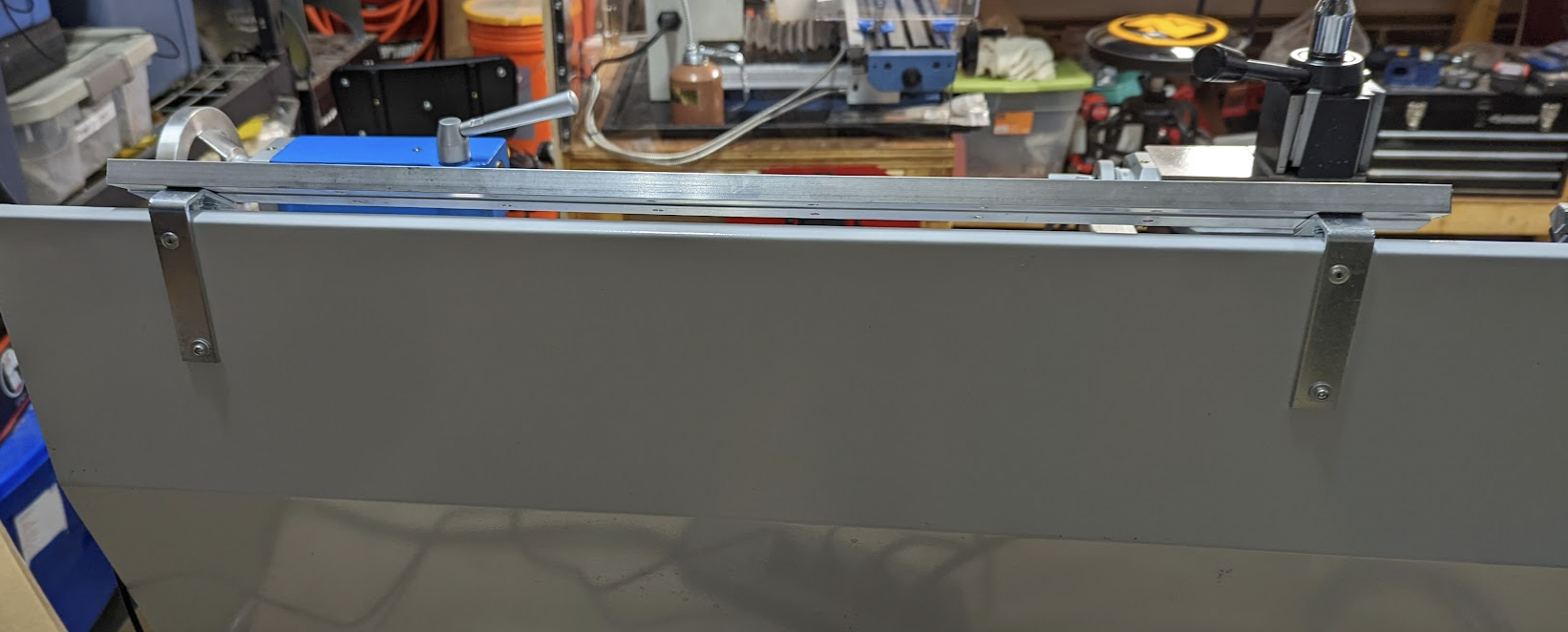

When I upgraded my CNC cutter bed, I had these 1/4" T-slot channels left over and I like to repurpose things. I bought some aluminum L-channel from the local home improvement store from the craft metal display and cut the holders to shape with a band saw and rounded the edges with a de-burring wheel on the bench grinder.

You can reverse the brackets as needed to accommodate larger tool holders. I attached this to the backsplash with some L-brackets from the home improvement store and pop rivets.

Tool Post Wrench

I almost didn't post this one but nothing is perfect. I saw a lot of examples of people heating wrenches and cutting them and there were 2 things that didn't appeal to me. I didn't like the low clearance that a lot of them had and I didn't like the scorch marks on the bends. Instead I have to look at my rookie knurling job.

This is simply a 17mm lug wrench with slotted end that I found on the popular 2-day delivery store for $14. It was an excuse to learn certain operations since I do better with an end product when learning something. The boring of the brass stock went well and the knurling went well until I started moving across the stock. It is unique and it is mine.

Chuck Key Holders

I'm actually very happy with the ways these turns out. Others have shown similar ones but over the years I've moved to open-source tools after being a victim of abandonware and pay-lots-o-money-ware. I do machining for fun, not profit. I create a parametric FreeCAD model for these holders and you simply need to type in the size of the chuck key to get a custom-fitted holder. Then 3D print it! Get the CAD model and everything else here: PM1030V PM1022V Lathe Chuck Key Holders

Tool Holder Rack

When I upgraded my CNC cutter bed, I had these 1/4" T-slot channels left over and I like to repurpose things. I bought some aluminum L-channel from the local home improvement store from the craft metal display and cut the holders to shape with a band saw and rounded the edges with a de-burring wheel on the bench grinder.

You can reverse the brackets as needed to accommodate larger tool holders. I attached this to the backsplash with some L-brackets from the home improvement store and pop rivets.

Tool Post Wrench

I almost didn't post this one but nothing is perfect. I saw a lot of examples of people heating wrenches and cutting them and there were 2 things that didn't appeal to me. I didn't like the low clearance that a lot of them had and I didn't like the scorch marks on the bends. Instead I have to look at my rookie knurling job.

This is simply a 17mm lug wrench with slotted end that I found on the popular 2-day delivery store for $14. It was an excuse to learn certain operations since I do better with an end product when learning something. The boring of the brass stock went well and the knurling went well until I started moving across the stock. It is unique and it is mine.