- Joined

- Sep 28, 2013

- Messages

- 4,394

thought I'd put all these pics here in one place.

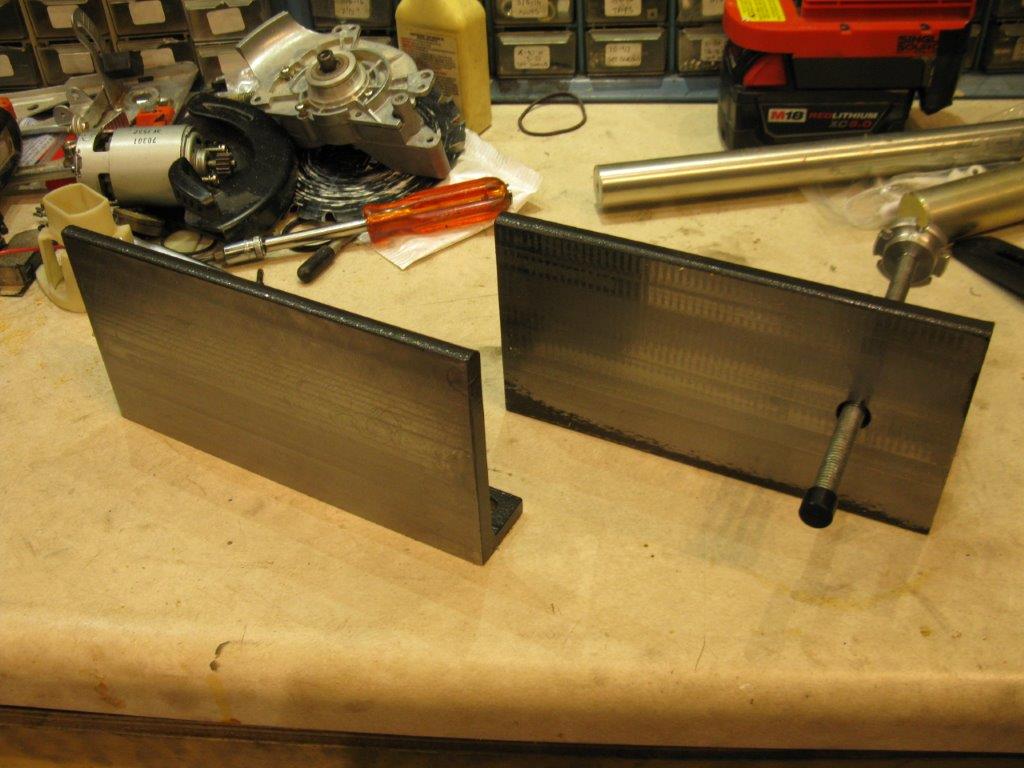

Finally got annoyed at the tiny crappy vise jaws on my HF 4x6 bandsaw when I couldn't cut off the last lot of QCTP holders as I couldn't hold the piece. So I dug out a nice piece of 4x4x3/8" angle iron that I found at the side of the road. Cut that in half (kinda), cut off an inch and a half from one side then added some cutouts and holes for the saw guides to fit and so on. Then used the cut offs to make some braces to weld in the back of the jaws.

First time welding, using a friend's flux core welder

compared to the original moving jaw

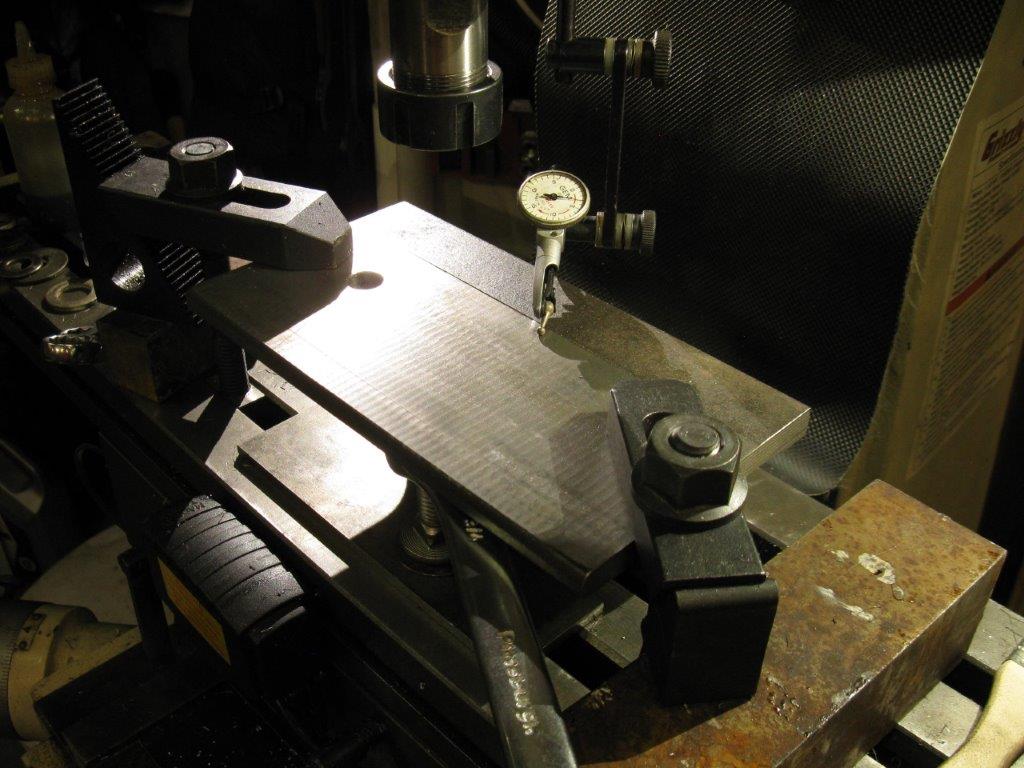

squaring up the sides. This turned into quite a palaver and led to all kinds of shenanigans, but it finally got done. Now I need to make some machinists jacks..

finally done and painted, phew! Jack screw is installed. It's a piece of 3/8-16 all thread, with a piece of 1/2 delrin at one end and alu handle at the other. The halfnut is another piece of steel cut off from the jaws, drilled and tapped 3/8-16 then cut in half with rare earth magnets in each half to hold it together. When it's open the rod can be tipped off of the halfnut and moved freely, then put back down at about the right distance. The halfnut is then closed and the rod screwed in or out to get the jaws parallel when holding a short piece close to the blade.

finally done and painted, phew! Jack screw is installed. It's a piece of 3/8-16 all thread, with a piece of 1/2 delrin at one end and alu handle at the other. The halfnut is another piece of steel cut off from the jaws, drilled and tapped 3/8-16 then cut in half with rare earth magnets in each half to hold it together. When it's open the rod can be tipped off of the halfnut and moved freely, then put back down at about the right distance. The halfnut is then closed and the rod screwed in or out to get the jaws parallel when holding a short piece close to the blade.

installed, halfnuts open and tip of the rod flush with the face of the moving jaw

installed, halfnuts open and tip of the rod flush with the face of the moving jaw

halfnuts closed and rod extended

also split the vise nut to remove alot of play. Not so much front and back but tilting, so the moving jaw would spring open at the top. Also shaved off 0.3mm from the top of the nut so the moving jaw would sit flat on the saw. Had to use set screws as I threaded the wrong side and the cap screw heads stopped the jaws closing all the way. Oops.

and to finish it off, made a T-nut for the fixed jaw if I ever need to swivel it for an angled cut. I haven't yet, but the original nut and bolt would be a pain to use.

and to finish it off, made a T-nut for the fixed jaw if I ever need to swivel it for an angled cut. I haven't yet, but the original nut and bolt would be a pain to use.

at some point I need to make a proper handle for the feed rate spring, but it hasn't annoyed me enough yet!

Finally got annoyed at the tiny crappy vise jaws on my HF 4x6 bandsaw when I couldn't cut off the last lot of QCTP holders as I couldn't hold the piece. So I dug out a nice piece of 4x4x3/8" angle iron that I found at the side of the road. Cut that in half (kinda), cut off an inch and a half from one side then added some cutouts and holes for the saw guides to fit and so on. Then used the cut offs to make some braces to weld in the back of the jaws.

First time welding, using a friend's flux core welder

compared to the original moving jaw

squaring up the sides. This turned into quite a palaver and led to all kinds of shenanigans, but it finally got done. Now I need to make some machinists jacks..

halfnuts closed and rod extended

also split the vise nut to remove alot of play. Not so much front and back but tilting, so the moving jaw would spring open at the top. Also shaved off 0.3mm from the top of the nut so the moving jaw would sit flat on the saw. Had to use set screws as I threaded the wrong side and the cap screw heads stopped the jaws closing all the way. Oops.

at some point I need to make a proper handle for the feed rate spring, but it hasn't annoyed me enough yet!