- Joined

- Oct 10, 2018

- Messages

- 545

Hi:

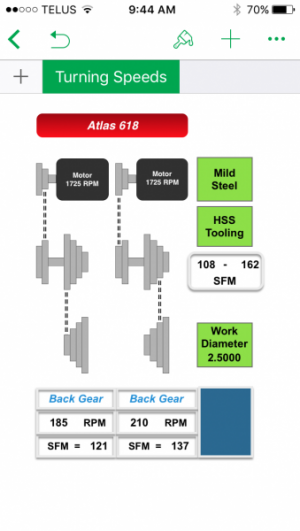

I found a couple of old threads on this subject but nothing since 2015. Since apps come and go fairly often, I'd like to ask what people are using now. I've only got a lathe at this point. I'd prefer something that makes it simple to select an appropriate rpm given the material (brass, aluminum, mild steel, ...) and a diameter. Well, also between carbide and HSS, I suppose.

I'm on iOS but I expect most such apps are on both major platforms now.

Craig

I found a couple of old threads on this subject but nothing since 2015. Since apps come and go fairly often, I'd like to ask what people are using now. I've only got a lathe at this point. I'd prefer something that makes it simple to select an appropriate rpm given the material (brass, aluminum, mild steel, ...) and a diameter. Well, also between carbide and HSS, I suppose.

I'm on iOS but I expect most such apps are on both major platforms now.

Craig