Sorry about the time, I only get on every week or two. Depending on your application, metal, plastic, or wood... or even "Play-Doh" would fill the bill. I do a lot of soldering small pieces of brass, both in model building and old fashioned instrument repair. We won't go so far back as building a meter movement, but d'arsenval meters have ....

I have a number of small clamps I have built similar to the store-boughten ones but small. 0.125 key stock and nr. 2 screws. And a lot of file work. Also I use a pile of hair clips (curlers?) to hold sheet (shim stock) together. They used to be made of aluminium so wouldn't stick to solder. The Chinese made ones are steel, and do stick. Yeah, well.... Both of those when close pins are too large.

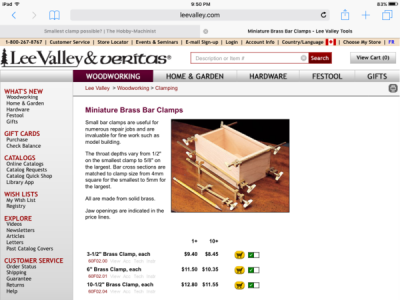

Micro-Mark is mentioned above, but there are many other suppliers for model builders. There is a beam clamp like carpenters (well, jointers) use but much smaller and made of plastic. Also, some aluminium "C" clamps from "X-Acto" but at 0.250 wide, probably too big. Sprung wheelsets on train locomotive frames are often reset with toothpicks. And coupler springs are half or less that size. I use a ground off flat dental probe there.

I could go on for hours about model trains. But take up way too much space here. My suggestion is to find a model builder and ask how such small items are handled. For what it's worth, most of our springs are smaller in diameter than the flint spring on a Bic lighter....

Bill Hudson