- Joined

- Nov 28, 2016

- Messages

- 2,793

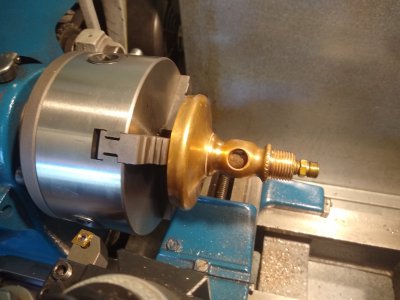

The gear cover on my old South Bend 14-½ lathe was cracked when I bought it. Over the last few years, the crack had grown until it was about to break completely in half...

I decided it was about time to do something about it.

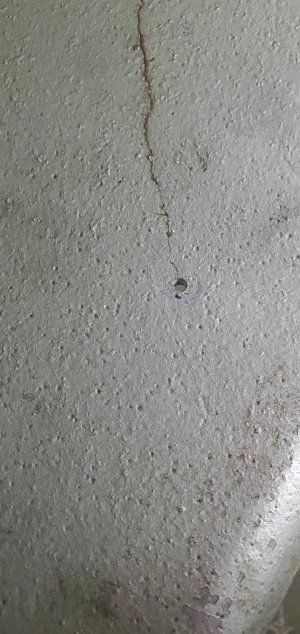

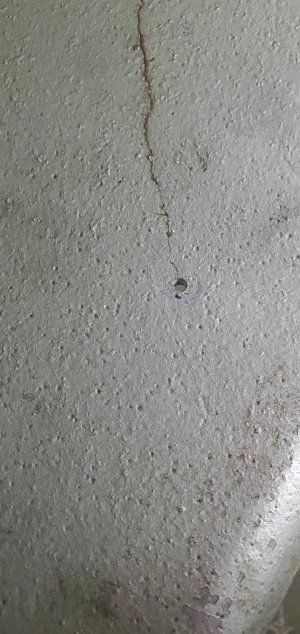

I started by drilling a stop-crack hole at the end of the crack...

Then I cut off a piece of 1-¼ x ⅛ steel flat stock and drilled two holes in it... clearance for #8-32 screws. I transferred the holes to the cover, drilled the cover to match, and screwed the flat stock to the cover, bridging the crack...

My next step was going to be grinding the crack out in a 'v', then TIG brazing it up with silicon bronze... but I remembered the batteries in my welding helmet were dead...

I'll have to get some batteries and braze it up later... for now, it is reinforced enough to keep the crack from going any farther.

-Bear

I decided it was about time to do something about it.

I started by drilling a stop-crack hole at the end of the crack...

Then I cut off a piece of 1-¼ x ⅛ steel flat stock and drilled two holes in it... clearance for #8-32 screws. I transferred the holes to the cover, drilled the cover to match, and screwed the flat stock to the cover, bridging the crack...

My next step was going to be grinding the crack out in a 'v', then TIG brazing it up with silicon bronze... but I remembered the batteries in my welding helmet were dead...

I'll have to get some batteries and braze it up later... for now, it is reinforced enough to keep the crack from going any farther.

-Bear