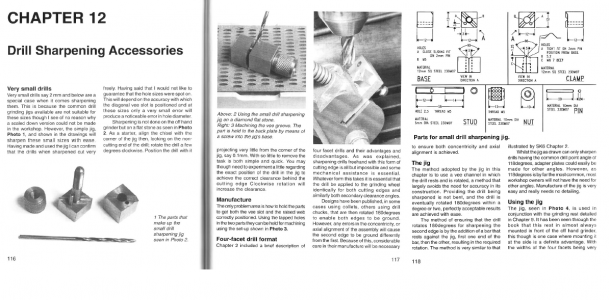

I hate using small drills, they break or even when new may have improper geometry. I came across a number of jigs to sharpen them, namely Lautard, Hall and Smeed’s. Since I was a bit sceptical I didn’t want to waste stock so I decided to make it from a few nuts and a piece of threaded rod.

Using the nuts allowed me to centre the groove that holds the drill quite easily and accurately. A side of the nut is aligned with the mill vise using a square, whilst an edge finder is used to find the nut’s centre.

You need a good glass to see what you are doing. I sharpened the drills on sandpaper and a diamond lapping plate. Had to fiddle a bit to get the drill geometry right but to my delight it worked. I soon dove into my hardened pin repository to fish out all the broken/dull drills I could salvage.

Using the nuts allowed me to centre the groove that holds the drill quite easily and accurately. A side of the nut is aligned with the mill vise using a square, whilst an edge finder is used to find the nut’s centre.

You need a good glass to see what you are doing. I sharpened the drills on sandpaper and a diamond lapping plate. Had to fiddle a bit to get the drill geometry right but to my delight it worked. I soon dove into my hardened pin repository to fish out all the broken/dull drills I could salvage.