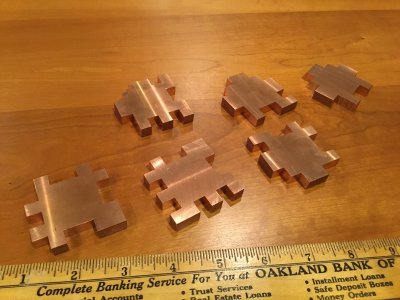

Just finished a classic puzzle cube. Made this one out of copper, which has such a beautiful color. And such substantial heft. And a very satisfying to click when the pieces come together. I machined the spaces to have an extra .005” on each side, so the fit has just a hair of wobble, and no binding. I did not need to do any hand filing to get to fit. Maybe with my current skills I could drop it down to 4 or maybe even 3 thou of extra clearance? Copper is such a bear to work on and get an adequate surface finish. I can recommend Copper 145 (or it is called Copper 14500, I don’t know the difference) which I am told has a fraction of a percent of tellurium mixed in to improve the machinability. Why tellurium I have simply no idea. I mean did they try aluminum and iron and magnesium and on and on and none of those worked and they finally ended up stumbling on tellurium? Or, is there some real materials theory that explains why tellurium is the right material? The 145 I think it helps a bunch (I played with some of my end mills on a small extra piece and chose the one least objectionable—a high twist 4 flute 1/4” carbide. I tried my 1 and 2 flute and they did not work as well.). Turns out it is actually a nice puzzle, solvable with a bit of diligence, but not trivial. -Bill

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small copper puzzle cube

- Thread starter Bill Kahn

- Start date

- Joined

- Nov 5, 2016

- Messages

- 1,420

Awesome! Do you have a drawing you can share?

Ted

Ted

- Joined

- Jan 2, 2014

- Messages

- 9,380

Wow!!!

That turned out fantastic!

Nice job, and thanks for posting.

-brino

EDIT: it would be neat to see one with mixed contrasting metals; brass on one side, aluminum on another, copper of course, etc..

That turned out fantastic!

Nice job, and thanks for posting.

-brino

EDIT: it would be neat to see one with mixed contrasting metals; brass on one side, aluminum on another, copper of course, etc..

- Joined

- Feb 2, 2017

- Messages

- 1,236

Ditto!Awesome! Do you have a drawing you can share?

Ted

- Joined

- Feb 27, 2014

- Messages

- 2,275

Very nice work. looks great. What are you doing to keep the surface from oxidizing if anything?

For information on the theory including plans for interlocking puzzles check out this site The Puzzling work of Polyhedral Dissections.

I have wanted to try some of the simpler Burr puzzles using dissimilar metals for a long time.

For information on the theory including plans for interlocking puzzles check out this site The Puzzling work of Polyhedral Dissections.

I have wanted to try some of the simpler Burr puzzles using dissimilar metals for a long time.

Here is what I have. I do not know the source. I think this is all in the public domain, but if someone thinks they have copyright on it please let me know.Awesome! Do you have a drawing you can share?

Ted

Note, of course, the whole thing scales just fine, so there are no units. Each square is 6 times its thickness.

Also note that it is up to the builder to figure out all the clearances required to actually make it work. For me, as a beginner, this took a bit of thinking, and initially, filing too.

I seem to be able to face the squares with thickness accurate to about 2 thou. So, I need to have that sort of clearance in each notch. Given my skills, an extra 5 thou cut off on each side of each “peg” has worked well. I think on my next try (which would be number 5) I may try to reduce to 4 thou. Getting the feel of the assembled puzzle to really “click” and sort of lock into place is hard. A few of my pieces fit together better than others and they are a joy to click together.

Of course, start with an easy material, like aluminum. I am showing off the copper, but while I love the heft and color, we all know it is a bear to come out nice.

I am sure everyone on this list already knows this, but I did not. You can’t make an accurate 1/4” slot with a 1/4” endmill. You need to be a bit undersized, do the through-cut where needed, then come back and finish each side exactly. And it takes a bit of futzing to get the depth exactly right.

Once you really get your head into this apparently simple drawing you will see it is really not a properly specified problem. When you play with the many 3-d ways the pieces fit together, just where you put the extra 5 thou of clearance becomes ambiguous.

I have thought about finishing the cube with a final facing pass on each of the 6 faces of the finished cube. But have not as the subtle tool marks make it too easy then to solve the puzzle—you match up machine marks rather than puzzling geometry. As the puzzle can be equally well assembled “inside-out” you would want to finish pass those sides too.

I have thought about polishing it all. Which is a lot of work. And it is really quite hard (well, for me) to fine sand down into each slot and then to polish nicely down into each corner. At that point it becomes more art than geometry and machining. If anyone does something like that please do post, I’d love to see it.

‘I did think about making each of the six pieces from a different metal (copper, aluminum, iron, magnesium, tin, zinc) but while clearly being extremely beautiful, saw that this again greatly simplifies the puzzle part of solving the puzzle as you will almost immediately learn which materials go together. Part of the joy of puzzling on this is learning the individuality of each piece, forward and backward, in each orientation. Each piece different, though on first blush appear the same. Almost reminds me of “Original Adventure” where one of the puzzles that need solving is the ”maze of twisty little passages all the same.” (Sorry for this old-guy computer-geek reference. It is a throw-back to computing in the 1960’s)

Whatever you do on this puzzle, please share.

Best, Bill

Attachments

- Joined

- Apr 28, 2014

- Messages

- 3,594

Then I imagine Will (@darkzero) will show up with his in titanium...Wow!!!

That turned out fantastic!

Nice job, and thanks for posting.

-brino

EDIT: it would be neat to see one with mixed contrasting metals; brass on one side, aluminum on another, copper of course, etc..

- Joined

- Nov 5, 2016

- Messages

- 1,420