- Joined

- Nov 18, 2012

- Messages

- 1,352

For quite some time I have been looking for metric 12 mm X 1 mm extra fine thread bolts with no luck. I want these so I can use some of the spindle accessories from my Unimat DB200 for other purposes / tooling.

I found out that there are banjo bolts with a 12 mm x 1 mm thread used on some imported cars. Spent a bunch of time yesterday driving around from car place to hydraulic guys, but to no avail.

I have cut imperial threads before on my Atlas 618 before and it sure is a PITA fooling around with the change gears. I didn't think my 618 could cut metric so I got out the book and did a read..WOW it can cut metric threads that are very very close to standard.

So I set up the gears and then read the process. Yikes totally different from cutting imperial threads. Forget the threading dial, never disengage the long feed, and always keep the tumbler engaged forward..do not disengage it. Instead at the end of one pass, stop the motor, put withdraw the crossslide and reverse the motor to back the carriage back to the start. Bring the cross slide back to zero and advance the compound.

I did a trial on a piece of aluminum to see if the gears were correct, and to get the hang of it. Is it ever hard to forget the old habit of disengaging the long feed, cranking the carriage back and engage according to the threading dial.

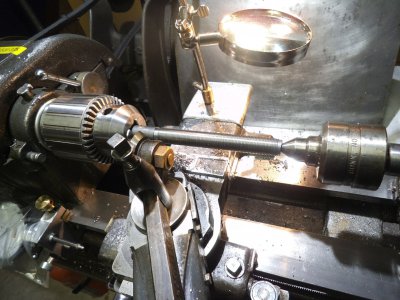

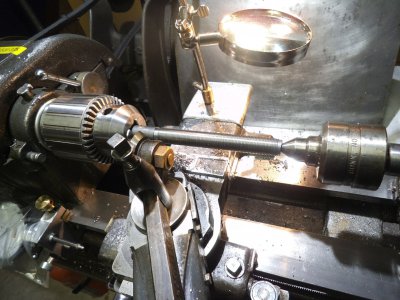

Everything worked out on the test piece so did the real deal on some 12L14. My old 618 came through again.

The pics show the 4 jaw chuck threaded on as a test and also the face plate.

David

I found out that there are banjo bolts with a 12 mm x 1 mm thread used on some imported cars. Spent a bunch of time yesterday driving around from car place to hydraulic guys, but to no avail.

I have cut imperial threads before on my Atlas 618 before and it sure is a PITA fooling around with the change gears. I didn't think my 618 could cut metric so I got out the book and did a read..WOW it can cut metric threads that are very very close to standard.

So I set up the gears and then read the process. Yikes totally different from cutting imperial threads. Forget the threading dial, never disengage the long feed, and always keep the tumbler engaged forward..do not disengage it. Instead at the end of one pass, stop the motor, put withdraw the crossslide and reverse the motor to back the carriage back to the start. Bring the cross slide back to zero and advance the compound.

I did a trial on a piece of aluminum to see if the gears were correct, and to get the hang of it. Is it ever hard to forget the old habit of disengaging the long feed, cranking the carriage back and engage according to the threading dial.

Everything worked out on the test piece so did the real deal on some 12L14. My old 618 came through again.

The pics show the 4 jaw chuck threaded on as a test and also the face plate.

David