- Joined

- Oct 16, 2017

- Messages

- 341

I have a Precision Mathews 1340GT lathe. After reviewing solid tool post projects I examined the compound on this lathe and notice movement across the compound ways when pressure is applied to the tool post (even with the slide locked). I began to see the advantage of a solid tool post. I did not want to build a solid tool post because of the time required to remove the compound and install the solid tool post. I also did no want to drill and tap the cross slide.

A viable solution to correcting the sloppy compound was to devise a clamp that would be quick and cheap to build, easy setup / take down and not require modification to the lathe.

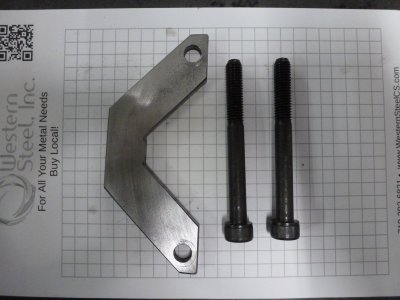

The clamp shown below is made from 1/4" mild steel and uses two 8mm X 300mm socket head cap screws to secure in place.

The clamp is installed by replacing the two compound lock screws.

All slop across the compound ways is eliminated and the surface finish is greatly improved.

A viable solution to correcting the sloppy compound was to devise a clamp that would be quick and cheap to build, easy setup / take down and not require modification to the lathe.

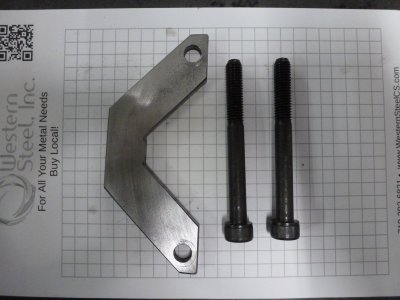

The clamp shown below is made from 1/4" mild steel and uses two 8mm X 300mm socket head cap screws to secure in place.

The clamp is installed by replacing the two compound lock screws.

All slop across the compound ways is eliminated and the surface finish is greatly improved.