- Joined

- Feb 1, 2018

- Messages

- 1,867

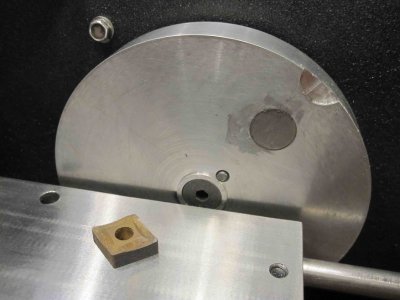

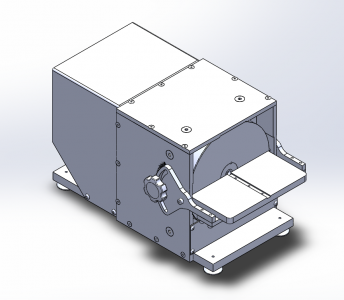

Now that Glendo stopped making Accu-finish lappers to sharpen carbide scraper blades many of you who made your own, please show them. I have an old Accu-finish 1 that uses 5" lapping wheels. I have had a few students build home made units that use Chinees engraving plates. Here is one that Stefan G made.