- Joined

- Jul 22, 2019

- Messages

- 33

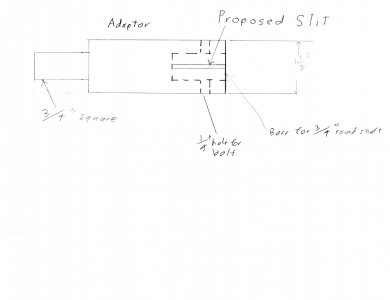

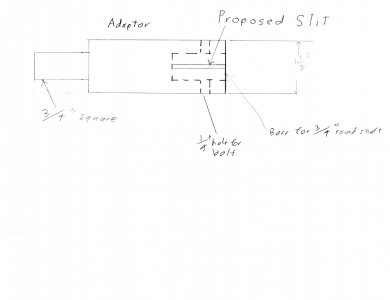

In the course of repairing my old RV, I found that the slide motor that I had was no longer available. I bought another slide motor, but it has 3/4" round output shafts instead of 3/4" square outputs. There is a fair amount of torque involved in moving a slide. The old 12V gearmotor was tagged as 58:1 gear reduction. Figure output of maybe 5 rpm.

I was planning to make an adaptor; take a few inches of 1.25" steel, bore one end for the shaft, and then mill a 3/4" square on the other end.

The 3/4" shaft has a hole for a 1/4" bolt. I am concerned that the shaft might move inside the adaptor, especially since my machining skills are limited, and it is certainly not going to be a press fit. Should I take the adaptor and cut a slit in the round end, such that the bolt will clamp the adaptor onto the shaft? I have attached a sketch.

I was planning to make an adaptor; take a few inches of 1.25" steel, bore one end for the shaft, and then mill a 3/4" square on the other end.

The 3/4" shaft has a hole for a 1/4" bolt. I am concerned that the shaft might move inside the adaptor, especially since my machining skills are limited, and it is certainly not going to be a press fit. Should I take the adaptor and cut a slit in the round end, such that the bolt will clamp the adaptor onto the shaft? I have attached a sketch.