- Joined

- Feb 2, 2013

- Messages

- 3,957

i recently had an itch to scratch.

i wanted a small vise, but didn't want to ignore the pile of scrap metal waiting to be re-purposed into useful things.

so i took a piece of vintage 6061 square 32mm bar and whacked a 120mm section from it

i squared the ends on the BP

i laid out the throat of the vise as well as center lines on all axes, for reference

i milled the billet to 25mm thickness

i then milled to 10mm thick in the center section and made the throat a total of 50mm long

there were holes in the billet from its last life, so i creatively removed material to where the holes were no longer present in the vise

i stood the billet on the immovable jaw end and plunge milled a landing for the screw-

that was an interesting cut-slow and steady - made a bunch of noises from the interrupted cut- but worked like a champ

- made a bunch of noises from the interrupted cut- but worked like a champ

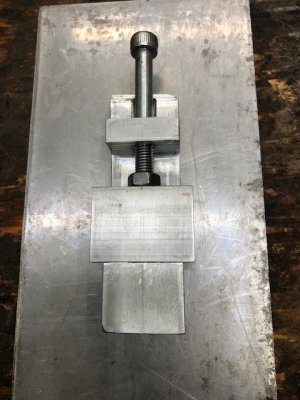

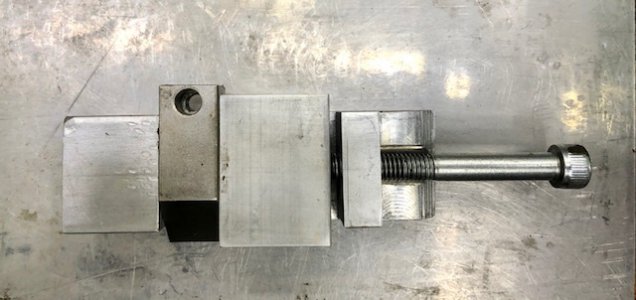

i drilled the screw bore 1mm above center to 5mm, then tapped to M6x1.0

i inserted a m6x1.0x65mm allen head bolt for the screw

i broke the edges and lightly sanded the vise

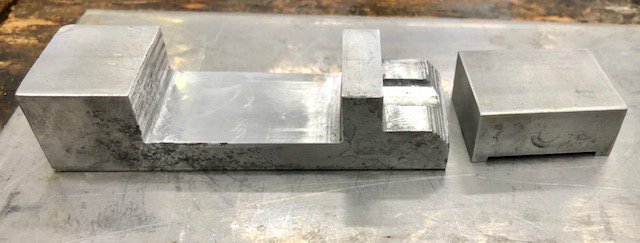

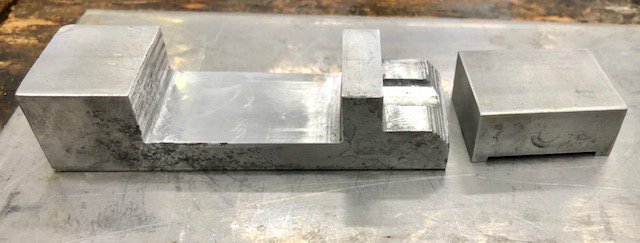

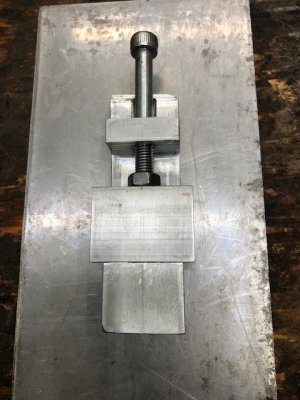

here is the result

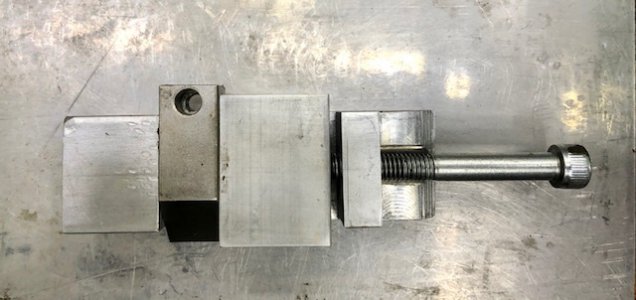

the vise closes to 30mm with the screw, but i wanted to also utilize the vise for smaller pieces

so i made a movable jaw from the same material milled to straddle the bed of the vise

i lightly lapped the movable jaw to the bed with good ol' Clover valve lapping compound (fine grit)

this is the progress until now, but there is more to come!

same Bat time, same Bat station....

i wanted a small vise, but didn't want to ignore the pile of scrap metal waiting to be re-purposed into useful things.

so i took a piece of vintage 6061 square 32mm bar and whacked a 120mm section from it

i squared the ends on the BP

i laid out the throat of the vise as well as center lines on all axes, for reference

i milled the billet to 25mm thickness

i then milled to 10mm thick in the center section and made the throat a total of 50mm long

there were holes in the billet from its last life, so i creatively removed material to where the holes were no longer present in the vise

i stood the billet on the immovable jaw end and plunge milled a landing for the screw-

that was an interesting cut-slow and steady

i drilled the screw bore 1mm above center to 5mm, then tapped to M6x1.0

i inserted a m6x1.0x65mm allen head bolt for the screw

i broke the edges and lightly sanded the vise

here is the result

the vise closes to 30mm with the screw, but i wanted to also utilize the vise for smaller pieces

so i made a movable jaw from the same material milled to straddle the bed of the vise

i lightly lapped the movable jaw to the bed with good ol' Clover valve lapping compound (fine grit)

this is the progress until now, but there is more to come!

same Bat time, same Bat station....