- Joined

- Mar 14, 2021

- Messages

- 27

Hello,

I’ve owned my Sherline 4000 Lathe for about 3 years. Never had any issues with the GiB adjustments till I installed the DRO kit. Since you need to disassemble the Lathe in several areas, I decided to do a good clean of everything & lubricate. I immediately noticed that my “Z” Axis dial was EXTREMELY HARD to turn. It will turn & the screw is moving it’s just Ridiculously hard.

So naturally I checked the GiB’s. [nothing had moved everything looked exactly the same] so I inspected everything closely & didn’t see any issues that would cause this?

I removed the GiB for that area & wiped it clean & did an inspection of the composite material GiB (looks new still not nicks or anything that would cause it to bind…- I probably only have 150 total hours on machine)

(BTW:the rails were sufficiently oiled )

With that GiB removed the Z-axis screw movement is Totally free & smooth.

I inspected the rails the GiB is pressed against & then made sure it was totally smooth & Oiled.

I reinstalled the GiB leaving the “Locking” Screw out, still with the GiB lock “L” wire in. Placed it in as many different positions I deemed possible. I could get a tiny amount of relief in a turn, but still about 90% too tight compared to how it’s operated past 3 years….

I couldn’t find any more info for this issue & im completely stumped…?

I couldn’t find any more info for this issue & im completely stumped…?

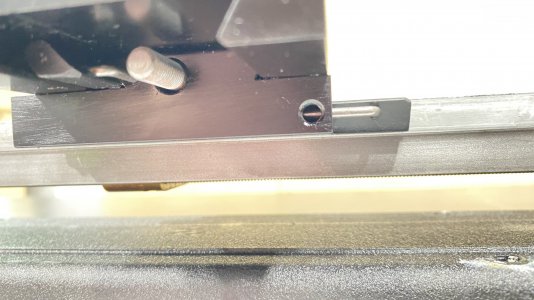

I’ve attached some photos I took of the area I’m referring too.

I’m hoping that someone with experience on a Sherline Lathe might have some troubleshooting options for me…

…PLEASE…

Many thanks!

Lee

SUMMARY: My Z-Axis wheel is wayyy to hard to turn, making GiB adjustments don’t seem to help?

I’ve owned my Sherline 4000 Lathe for about 3 years. Never had any issues with the GiB adjustments till I installed the DRO kit. Since you need to disassemble the Lathe in several areas, I decided to do a good clean of everything & lubricate. I immediately noticed that my “Z” Axis dial was EXTREMELY HARD to turn. It will turn & the screw is moving it’s just Ridiculously hard.

So naturally I checked the GiB’s. [nothing had moved everything looked exactly the same] so I inspected everything closely & didn’t see any issues that would cause this?

I removed the GiB for that area & wiped it clean & did an inspection of the composite material GiB (looks new still not nicks or anything that would cause it to bind…- I probably only have 150 total hours on machine)

(BTW:the rails were sufficiently oiled )

With that GiB removed the Z-axis screw movement is Totally free & smooth.

I inspected the rails the GiB is pressed against & then made sure it was totally smooth & Oiled.

I reinstalled the GiB leaving the “Locking” Screw out, still with the GiB lock “L” wire in. Placed it in as many different positions I deemed possible. I could get a tiny amount of relief in a turn, but still about 90% too tight compared to how it’s operated past 3 years….

I’ve attached some photos I took of the area I’m referring too.

I’m hoping that someone with experience on a Sherline Lathe might have some troubleshooting options for me…

…PLEASE…

Many thanks!

Lee

SUMMARY: My Z-Axis wheel is wayyy to hard to turn, making GiB adjustments don’t seem to help?

Attachments

Last edited: