- Joined

- Dec 18, 2019

- Messages

- 7,333

I know about the butt welding clamps for sheet metal. There you want a gap between the panels that (slowly) fills with spot/momentary welds.

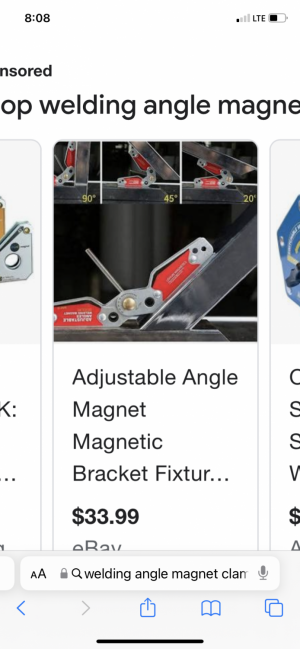

What do you do for angled joints? Are they gapped as well, or just butt them together? Are there clamps for non-right angle joints?

I am trying to weld on sheet metal extensions to an already existing backsplash for my G0752Z lathe. Due to a replacement DRO install, the backsplash needs to be spaced further back. I have done that already. But now I need to add sheet metal to parts of the backsplash to shield the motor, which has now become exposed to chips. I can do the butt weld extensions (haven't tried it yet but will this week) but I am puzzling about holding the non-right angle corners in place for welding. Do such clamps exist? What are they called?

Yes, I'm missing a picture. I'll take one tomorrow. Backsplash mikes at 0.047" thick. My sheet metal (18 ga) mikes at 0.053" thick. Will be using MIG.

What do you do for angled joints? Are they gapped as well, or just butt them together? Are there clamps for non-right angle joints?

I am trying to weld on sheet metal extensions to an already existing backsplash for my G0752Z lathe. Due to a replacement DRO install, the backsplash needs to be spaced further back. I have done that already. But now I need to add sheet metal to parts of the backsplash to shield the motor, which has now become exposed to chips. I can do the butt weld extensions (haven't tried it yet but will this week) but I am puzzling about holding the non-right angle corners in place for welding. Do such clamps exist? What are they called?

Yes, I'm missing a picture. I'll take one tomorrow. Backsplash mikes at 0.047" thick. My sheet metal (18 ga) mikes at 0.053" thick. Will be using MIG.