-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sharpening drill bits without a Drill Doctor?

- Thread starter Nelson

- Start date

That's a toughie, Nelson. I can't even describe it. That would be beyond photos, it seems to me. A video maybe. Before I started wearing bifocals, I could do a passable job down to 1/16", and get on size holes, but not any more. 1/8" is about my free hand limit.

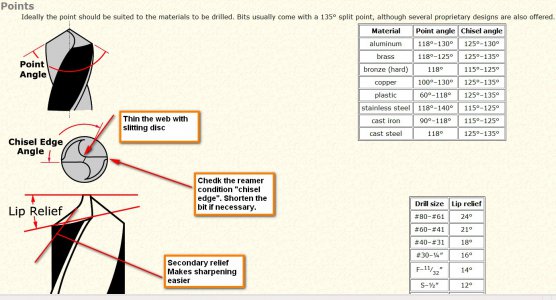

Start by studying the geometry of large drills, to see the clearance angles. Get a point gage to make sure your flanks are symmetrical. Get a magnifying glass to see the details.

Start by studying the geometry of large drills, to see the clearance angles. Get a point gage to make sure your flanks are symmetrical. Get a magnifying glass to see the details.

Check out this: [video=youtube;cqn2VPGYA9c]http://www.youtube.com/watch?v=cqn2VPGYA9c[/video] its from tubalcain on Youtube. He is a great source of machining info.

Mark

Mark

Last edited by a moderator:

I'll second Paddy's notion on the Drill Doctor. I've heard they make a better one for "industrial" use, but I've not seen it. I know there are very good drill sharpeners for toolroom use, but they're going to be beyond reach for most hobby shops. I learned to sharpen a long time ago, because the shops I worked in were too backward or too poor to afford a real drill grinder, so now I take it for granted. It's not really all that difficult once you understand cutting geometry. Get some burned up drills that you can't possibly hurt, and give it a try. Drill into a chuck of wood and see how they act.

One thing that I've developed a habit on is never moving my feet while at the wheel. Seems that if I stay planted, my hands can keep the proper relationship with the wheel and the angles and such come out pretty consistent. YMMV

One thing that I've developed a habit on is never moving my feet while at the wheel. Seems that if I stay planted, my hands can keep the proper relationship with the wheel and the angles and such come out pretty consistent. YMMV

One reason that I ask is that I just bought a bunch of used drills on Ebay- it was a package deal with about 500 drills, mostly US according to the vendor, but one chinese set. I'm assuming that they will need sharpening. In addition to the Baldor, which is 3 phase and not yet operational, I own a cheapo Grizzly $25 model that I hope would be ok just to sharpen up some bits IF I can learn how.

Thanks,

Nelson

Thanks,

Nelson

Tony

In my gallery photos is the Darex XT3000 Autofeed drill sharpener I got last year, it is a really nice set up and the only drill sharpener that I have liked.

Nelson

I can and do sharpen bits by hand, it is as others have said a learned art. Takes a bit of co-ordination and a twist of the wrist so to speak to get them done right. The big thing is to get the back relief angle just right while maintaining the proper point angle, 118 deg for most cases and keeping the flute lengths just right. I will second the Starrett drill guage or the one I use is the General Drill guage.

I had purchased a Drill Doctor 750 and it went back the next day, I could sharpen better and faster by hand, I was not impressed. they did say that the one I had was defective, but it was to flimsy and plasticy. I also tryed the Harmony Drill Grinder, but it would not sharpen the correct angles and did not touch bits below 1/4", and even 1/2" was touchy, so it went back as well. While I was trying out the Harmony, one of my clients came in with these big 2" diameter bits and I buzzed them off by hand. They were impressed with how well they drilled!

I have also used the B&D, and a bunch of others along with that little attachment that goes beside the grinder.

Finally, I bit the bullet and ordered in the Darex, along with most of the attachments for it. I went through and tuned up all my bits that I had in the shop. It does an awesome job. Quick and painless, well not quite painless if you look at the original cost of the sharpener.

My big thing is that I offer this as a service to my clients, to sharpen their drill bits and I did not want to be relying on my hand sharpening because even though the bits drilled good, you could tell they were hand sharpened. Now I can get the bits too look factory good and often they drill better than factory sharp.

Walter

In my gallery photos is the Darex XT3000 Autofeed drill sharpener I got last year, it is a really nice set up and the only drill sharpener that I have liked.

Nelson

I can and do sharpen bits by hand, it is as others have said a learned art. Takes a bit of co-ordination and a twist of the wrist so to speak to get them done right. The big thing is to get the back relief angle just right while maintaining the proper point angle, 118 deg for most cases and keeping the flute lengths just right. I will second the Starrett drill guage or the one I use is the General Drill guage.

I had purchased a Drill Doctor 750 and it went back the next day, I could sharpen better and faster by hand, I was not impressed. they did say that the one I had was defective, but it was to flimsy and plasticy. I also tryed the Harmony Drill Grinder, but it would not sharpen the correct angles and did not touch bits below 1/4", and even 1/2" was touchy, so it went back as well. While I was trying out the Harmony, one of my clients came in with these big 2" diameter bits and I buzzed them off by hand. They were impressed with how well they drilled!

I have also used the B&D, and a bunch of others along with that little attachment that goes beside the grinder.

Finally, I bit the bullet and ordered in the Darex, along with most of the attachments for it. I went through and tuned up all my bits that I had in the shop. It does an awesome job. Quick and painless, well not quite painless if you look at the original cost of the sharpener.

My big thing is that I offer this as a service to my clients, to sharpen their drill bits and I did not want to be relying on my hand sharpening because even though the bits drilled good, you could tell they were hand sharpened. Now I can get the bits too look factory good and often they drill better than factory sharp.

Walter

Last edited:

Walter, that's a nice rig. Last shop I was employed in had a Darex similar to that. The tool room guys got tired of sharpening drills for out machine "operators" who couldn't manage on their own. We also had a nice little Darex end mill grinder too. I almost snagged it for myself when we shut down.

Didnt Tubal Cain throw one of those jig thingys in the bucket? all I did was use a piece of alum. flashing

measured the degree with a protractor & cut it with a razor knife, thats my gage like a big fish and

stamped the degree angle on it made a few for different angle drills.

measured the degree with a protractor & cut it with a razor knife, thats my gage like a big fish and

stamped the degree angle on it made a few for different angle drills.

Last edited by a moderator:

I found this great article on Gadgetbuilder.com that describes a jig that he made to sharpen drills:

http://www.gadgetbuilder.com/DrillSharp.html

He has a couple of them shown on the site, along with one just for small drill bits.

Best,

Nelson

http://www.gadgetbuilder.com/DrillSharp.html

He has a couple of them shown on the site, along with one just for small drill bits.

Best,

Nelson

If that tubalcain fellow came into my shop bustin stuff up and throwing things in a trash can, I'd toss him out on his rear. Just because he doesn't like that particular jig doesn't mean it's junk. Maybe he just doesn't know how to use it.

I disagree with a couple of things he showed, but since so many people worship him, I won't correct him.

I disagree with a couple of things he showed, but since so many people worship him, I won't correct him.