- Joined

- May 7, 2014

- Messages

- 776

I am going to make a few things that would benefit from a corner rounding operation on a main plate of Alu 6061. I purchased a 1/8" radius 5/8 OD by .5 shaft Hertel for use on a 1/4 or 3/8 inch Alu plate. I watched several videos on using the manual method via Toms Techn's but cannot find much on the setup for CNC?

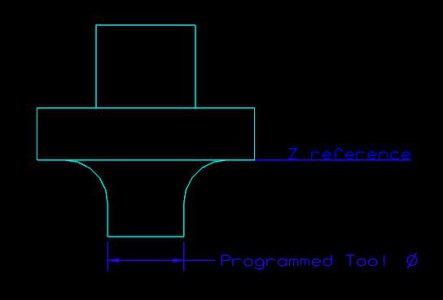

I'll play with scrap first w/ some trials but is the general idea to enter the tool as a end mill w/ 5/8" diameter. Use the tool offset setup of my Centroid setup and get the 0 to the top of the part. Take the OD .625 (-) the 1/8" and then (+ )a few "thou" back to stay just above the top of the material (not too deep say's Toms vid to rid burr edges) as my values for Z and X? depths of cut. Say .123? Maybe tell my Cam to run that in 2 passes or stick w/ 1? (a 3 flute cutter device)

Thanks everyone. The 3D printer took a ride w/ the kid for a few weeks. bummer! Back to some metal work projects.

Back to some metal work projects.

I'll play with scrap first w/ some trials but is the general idea to enter the tool as a end mill w/ 5/8" diameter. Use the tool offset setup of my Centroid setup and get the 0 to the top of the part. Take the OD .625 (-) the 1/8" and then (+ )a few "thou" back to stay just above the top of the material (not too deep say's Toms vid to rid burr edges) as my values for Z and X? depths of cut. Say .123? Maybe tell my Cam to run that in 2 passes or stick w/ 1? (a 3 flute cutter device)

Thanks everyone. The 3D printer took a ride w/ the kid for a few weeks. bummer!

thanks.

thanks.