- Joined

- Jan 3, 2015

- Messages

- 400

This didn't work over in the general machining forum, so I'll try here.

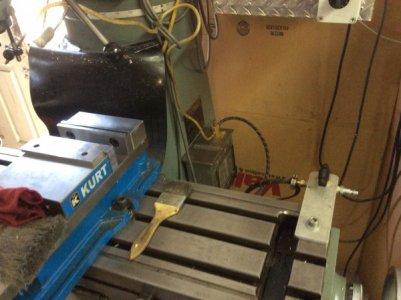

I've been running a Fogbuster for a year now, and I keep bumping into places where it doesn't spray into the cut well enough. It's fine for thin stock and shallow cuts, but I regularly get into cuts where the spray gets blocked by part of the work piece. I have a Grizzly G0704 and there are only seem to be a couple of places that I can stick the magnetic holder for the Fogbuster nozzle. Essentially on the left, on the bottom of the motor speed control box, or on the right side of vertical slide.

Both places seem to end up with 6 or 8" to spray and come to the cutter at an angle that cuts off the spray on some cuts.

Has anyone been able to come up with a way to route the Fogbuster closer to the cutter? Maybe something in place of the long brass tube?

I can't see how I could put on those adjustable tubes like those used with flood coolant.

I've been running a Fogbuster for a year now, and I keep bumping into places where it doesn't spray into the cut well enough. It's fine for thin stock and shallow cuts, but I regularly get into cuts where the spray gets blocked by part of the work piece. I have a Grizzly G0704 and there are only seem to be a couple of places that I can stick the magnetic holder for the Fogbuster nozzle. Essentially on the left, on the bottom of the motor speed control box, or on the right side of vertical slide.

Both places seem to end up with 6 or 8" to spray and come to the cutter at an angle that cuts off the spray on some cuts.

Has anyone been able to come up with a way to route the Fogbuster closer to the cutter? Maybe something in place of the long brass tube?

I can't see how I could put on those adjustable tubes like those used with flood coolant.