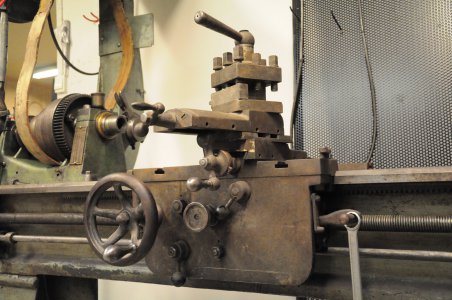

A litle post about my Sebastian flat belt lathe, age un-known (probably early 1900s??).

I bought this lathe a couple of years ago. It was a real basket case, having been (mis)used over several years.

The price was equivalent to about 300 USD, wich is kind of cheap here in Norway.

I figured I could stand to lose the money if it was too much of a project.

At least I could sell it for scrap metal

The first issue was to get the thing cleaned up, in order to see the state of things.

After hours of scraping, rubbing and a couple of liters of kerosene and countless worn out rags, most of the crud was removed.

To my big surprise, things were not all that bad, and there seemed to be ligth in the end of the tunnel.

The spindle and spindle bearings were OK, only needed to shim for correct clearence and it was back in buisness.

The Apron was full of crud, but after a thurough cleaning and relubrication things went back to gether and worked flawlessly.

Feedscrew and powerfeed shaft were both in working order.

Crosslide screws and nuts have backlash, but it is livable.

This lathe relies on change gears in order to change the threading pitches, sadly I am missing most of the gears. So making gears is a future mill project. (just need to get rotary table first).

Luckaly I have managed to get by so far with the ones I have.

The power feed drive mechanism was also missing, so I made a rather poor "temporary" solution to get by.

The temporary fix is still in use, and works excellent. So I guess it will stay that way for some time to come

I bought this lathe a couple of years ago. It was a real basket case, having been (mis)used over several years.

The price was equivalent to about 300 USD, wich is kind of cheap here in Norway.

I figured I could stand to lose the money if it was too much of a project.

At least I could sell it for scrap metal

The first issue was to get the thing cleaned up, in order to see the state of things.

After hours of scraping, rubbing and a couple of liters of kerosene and countless worn out rags, most of the crud was removed.

To my big surprise, things were not all that bad, and there seemed to be ligth in the end of the tunnel.

The spindle and spindle bearings were OK, only needed to shim for correct clearence and it was back in buisness.

The Apron was full of crud, but after a thurough cleaning and relubrication things went back to gether and worked flawlessly.

Feedscrew and powerfeed shaft were both in working order.

Crosslide screws and nuts have backlash, but it is livable.

This lathe relies on change gears in order to change the threading pitches, sadly I am missing most of the gears. So making gears is a future mill project. (just need to get rotary table first).

Luckaly I have managed to get by so far with the ones I have.

The power feed drive mechanism was also missing, so I made a rather poor "temporary" solution to get by.

The temporary fix is still in use, and works excellent. So I guess it will stay that way for some time to come