- Joined

- Nov 15, 2020

- Messages

- 148

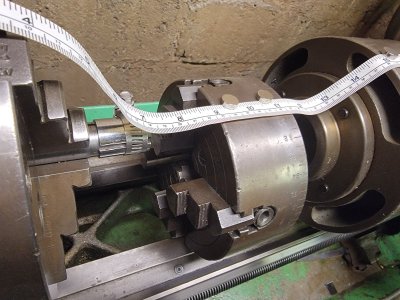

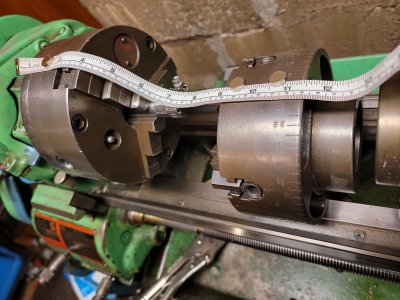

I'm a long time user of a 9A and a Heavy10 with a Camlock. I recently acquired another Heavy10 with a 2-1/4"x8 threaded spindle. The chucks all seem at least 1-1/2" thicker than the Camlock and 2"-3" thicker than the 1-1/2"-8 spindle on my 9.

Part of this seems to be that the 2-1/4"-8 chucks have a noticeable shoulder on the back where the threads are contained, versus them being mostly flush with the 1-1/2"-8 and cam lock.

Feels like I'm losing quite a bit of space. Is this common because of the larger diameter spindle or did I just end up with chucks that are really thick?

Part of this seems to be that the 2-1/4"-8 chucks have a noticeable shoulder on the back where the threads are contained, versus them being mostly flush with the 1-1/2"-8 and cam lock.

Feels like I'm losing quite a bit of space. Is this common because of the larger diameter spindle or did I just end up with chucks that are really thick?