- Joined

- Mar 5, 2024

- Messages

- 13

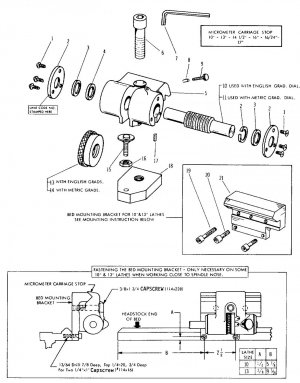

Hello all! I have been learning about my South Bend Heavy 10 lathe over the last month or so. One of the things that I discovered is that my Saddle Lock is missing. Initially I thought that only the locking bolt was missing, but digging in further I find that the whole thing is missing. I suppose it is possible that it fell out, somewhere along the line, long before I got the lathe. I found a drawing for a Saddle Lock for the heavy 10 on this site by Gary W. Johnson, for which I am very thankful to have found.

My question is if I make the part, does it require removing the saddle from the lathe to install? In the drawing Gary mentions the possible need to examine the cavity where the lock is mounted for adjusting the width of the stop. Is it a tight fit in the saddle? I will also need to fabricate the bolt, as well. Any suggestions or advise would be appreciated.

Another item I have been interested in is a Micrometer Carriage Stop. Before pursuing one on Ebay or somewhere else, I thought I would ask if these are useful items to have on this lathe? My bed seems to be drilled and tapped for one, but of course it is not present. If it is just a luxury item, I will probably forgo it, or possibly fabricate one for myself one day. Would a dial indicator mount for the carriage be more useful?

Thank you all in advance.

My question is if I make the part, does it require removing the saddle from the lathe to install? In the drawing Gary mentions the possible need to examine the cavity where the lock is mounted for adjusting the width of the stop. Is it a tight fit in the saddle? I will also need to fabricate the bolt, as well. Any suggestions or advise would be appreciated.

Another item I have been interested in is a Micrometer Carriage Stop. Before pursuing one on Ebay or somewhere else, I thought I would ask if these are useful items to have on this lathe? My bed seems to be drilled and tapped for one, but of course it is not present. If it is just a luxury item, I will probably forgo it, or possibly fabricate one for myself one day. Would a dial indicator mount for the carriage be more useful?

Thank you all in advance.