-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Roughing End Mills

- Thread starter ddickey

- Start date

B

Bill Gruby

Forum Guest

Register Today

Your question covers a lot of territory. Narrow it down for us. Use, size mill etc.

"Billy G"

"Billy G"

4

4GSR

Forum Guest

Register Today

Roughing mills work great. Just remember, they may cut oversize if milling slots, especially deep slots. Don't be afraid to cut double or triple that of an regular EM in depth. They are made for hogging! Take advantage of that if your mill can handle it, but not to the point of busting the end mill! Use a spray mist setup for keeping the EM cool and evacuation of chips. That's the nice thing about roughing mills, they make small chips, too, for easy cleanup!

Thinking about this one.

https://www.maritool.com/Cutting-To...ide-rougher-.625-loc-w/flat/product_info.html

https://www.maritool.com/Cutting-To...ide-rougher-.625-loc-w/flat/product_info.html

- Joined

- Dec 20, 2012

- Messages

- 9,422

Duane, there are fine and coarse pitched roughing end mills for steels and aluminum, too. Fine pitch is better for lighter cuts in hard materials and will leave a better finish so that clean up with a standard end mill is easier. Coarse pitch is used for deep slots or profiling when you have to take off a lot of material, usually in softer steels. Aluminum roughers tend to have a different sinusoidal pattern or a higher helix angle but are otherwise similar - coarse for hogging or deep cuts, fine for shallower cuts. You can use a standard rougher on aluminum but the roughers intended for aluminum clear chips much better and are worth buying if you're working with a lot of aluminum.

I would suggest you buy your stuff on ebay. Look for lots and only buy new ones unless you have the capability of sharpening them. There are many good brands - Melin, Regal, OSG, Niagara and so on. Don't be sucked in to buying used end mills - you cannot see the wear on them in a picture, especially at the tips.

Here is one that you might consider: http://www.ebay.com/itm/roughing-en...320743?hash=item25cefa9d67:g:SmwAAOSwjDZYcVtp

Hertel is a known brand. These are coarse pitch end mills, good for heavy profiling cuts that you have in mind.

As always, use the largest end mill that will suit your application. Also keep in mind that a rougher leaves a rough finish that has to be cleaned up with a finishing end mill. Coarse pitch roughers require around 0.015 - 0.020" to clean up, while fine pitch needs about 0.010 - 0.015" to clean up so plan accordingly. For example, if you need a 3/8" wide slot with a clean finish, use a 5/16" rougher so you have enough meat to clean up the roughing marks with either a 3/8" finishing end mill if only clean edges are required or a 5/16" finisher if the slot has to be very accurately sized.

Roughers create a LOT of chips. A vacuum or stream of air will reduce re-cutting and help your end mills last longer. You can also use a coolant stream but it gets messy.

Oh, I strongly suggest that you buy yourself a bandsaw. It is far cheaper to cut it off than to mill it off.

I would suggest you buy your stuff on ebay. Look for lots and only buy new ones unless you have the capability of sharpening them. There are many good brands - Melin, Regal, OSG, Niagara and so on. Don't be sucked in to buying used end mills - you cannot see the wear on them in a picture, especially at the tips.

Here is one that you might consider: http://www.ebay.com/itm/roughing-en...320743?hash=item25cefa9d67:g:SmwAAOSwjDZYcVtp

Hertel is a known brand. These are coarse pitch end mills, good for heavy profiling cuts that you have in mind.

As always, use the largest end mill that will suit your application. Also keep in mind that a rougher leaves a rough finish that has to be cleaned up with a finishing end mill. Coarse pitch roughers require around 0.015 - 0.020" to clean up, while fine pitch needs about 0.010 - 0.015" to clean up so plan accordingly. For example, if you need a 3/8" wide slot with a clean finish, use a 5/16" rougher so you have enough meat to clean up the roughing marks with either a 3/8" finishing end mill if only clean edges are required or a 5/16" finisher if the slot has to be very accurately sized.

Roughers create a LOT of chips. A vacuum or stream of air will reduce re-cutting and help your end mills last longer. You can also use a coolant stream but it gets messy.

Oh, I strongly suggest that you buy yourself a bandsaw. It is far cheaper to cut it off than to mill it off.

Last edited:

- Joined

- Nov 14, 2014

- Messages

- 851

What Mikey said about buying a band saw. plus Craigslist is your friend for cheap used grinders. Hard to do anything without a grinder with grinding wheel and decent brush wheel..

Last year I got tired of throwing away used up small end mills when hogging out work on my mill. So bought a bunch of 3/4" roughing end mills via eBay. Still using the first one I put in the machine. They are great for metal removal. Go with the largest size you can install in your collets, and happy milling!

BTW-I've got a bunch of 1" OD . r8 collets don't go that large. At least my set doesn't fit 1" OD. So they just sit there, using up space and sunLight.

Glenn

Last year I got tired of throwing away used up small end mills when hogging out work on my mill. So bought a bunch of 3/4" roughing end mills via eBay. Still using the first one I put in the machine. They are great for metal removal. Go with the largest size you can install in your collets, and happy milling!

BTW-I've got a bunch of 1" OD . r8 collets don't go that large. At least my set doesn't fit 1" OD. So they just sit there, using up space and sunLight.

Glenn

Last edited:

- Joined

- Aug 29, 2013

- Messages

- 1,050

What Mikey said about buying a band saw.

Or even a hacksaw. I have also used a sawzall (well, Craftsman reciprocating saw) with a metal cutting blade and the work held in a bench vise.

I'd guess you can find bench grinders anywhere on craigslist for under $40. I have two bench grinders and one is an 8" Harbor Freight I bought for around $40 with a coupon.

Incidentally my first "machine" back in the mid 1970s was a sort of bench grinder. It was a refrigerator motor with an arbor holding a grinding wheel on the shaft with a home made wooden base. Hey, it worked for me.

- Joined

- Jun 12, 2014

- Messages

- 5,071

You need to look at the Hp and rigidity of your machine, but a 3/4" rougher in a R-8 machine works very well for fast removal of material. They do make a 1" R-8 collet which does not work very well for any lateral loading, I do use an ER-40 for a 1" end mill. On roughers, my go to is a Niagara 3/4" shank 7/8" 5FL fine rougher, makes very quick work of metal removal. Below is a picture of milling 0.20 x 0.60 DOC 10 IPM passes in aluminum at around 1800 RPM and I could have pushed quicker. Just about any rougher will work well, the choice of profile, flutes and coating is material specific. Whatever you get, you may want a 3Fl for Aluminum and a 4 or 5 flute for steel. Go with a good name brand, they last a long time.

My other go to end mill for fast material removal are the Minicut Rougher 930P in a 3/4" 3FL or 4 FL, they have an unusual staggered wave pattern on the cutter edge which gives a very clean edge finish. They are powdered metal cobalt and hold up well.

4 Flute: http://www.ebay.com/itm/3-4-X-3-4-X-1-5-8-X-3-7-8-4FLT-HS-MINICUT-EM-W212-1-/260812487673

3 Flute for Aluminum http://www.discount-tools.com/endmills/min-930p.cfm

Start

Finished roughing

Finished (well almost)

My other go to end mill for fast material removal are the Minicut Rougher 930P in a 3/4" 3FL or 4 FL, they have an unusual staggered wave pattern on the cutter edge which gives a very clean edge finish. They are powdered metal cobalt and hold up well.

4 Flute: http://www.ebay.com/itm/3-4-X-3-4-X-1-5-8-X-3-7-8-4FLT-HS-MINICUT-EM-W212-1-/260812487673

3 Flute for Aluminum http://www.discount-tools.com/endmills/min-930p.cfm

Start

Finished roughing

Finished (well almost)

- Joined

- Feb 5, 2017

- Messages

- 30

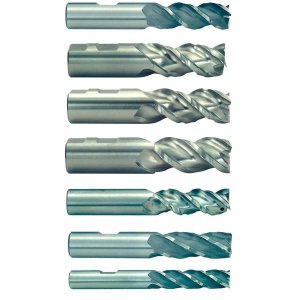

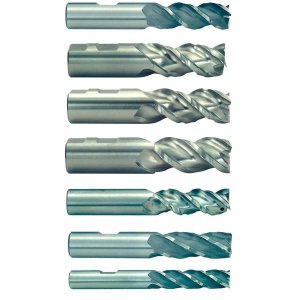

Great info! Just as I'm looking for a roughing end mill. Anyone have any experience with the roughing end mills from Shars? They have a set of 4 for what seems reasonable.

http://www.ebay.com/itm/351102973978

Or should one stick to Melin, Regal, OSG, Niagara, Hertal?

http://www.ebay.com/itm/351102973978

Or should one stick to Melin, Regal, OSG, Niagara, Hertal?