- Joined

- Feb 25, 2021

- Messages

- 3,271

I figured I'd start a new thread to separate this from my rotary table controller thread. It might be of interest to some others here as it evolves over the next few months.

Not too long ago I purchased a "project" VMC, one that will need plenty of TLC. It draws something like 60amps @ 240V three phase. That is not a small phase converter. My current phase converter uses a 20HP idler. I built a new shop in the last year, so I ran wire suitable for up to 125A (at single phase 240V) to the phase converter. So I should be able to expand my RPC by adding an idler.

I equipped my phase converter with voltage and amperage displays. But unless you are standing in front of the panel staring at the displays, they are of limited value. Certainly don't need to be trying to turn something on the big lathe while staring at the RPC. (My <5HP machines use VFDs, so only the big things require the RPC).

So in parallel with another microcontroller project, I've used a Raspberry Pi Pico and am working on a three phase logging tool. Using a 6 channel differential A/D converter and some isolation transformers I'm able to capture voltage and current on all three legs sampled at 1.041 ms (16 samples/cycle of 60Hz). Well, so far I've used a cheap furnace transformer as a bench test. Anyway, roughly every 1/2 second I'm getting a dump of voltage/current, phase and noise for all 6 channels. Goal is to use a Pico W to send the data wirelessly to a Raspbery Pi 4 B to capture along with a real-time timestamp. A simple web server on the RPI 4B can give stats, history, etc, etc. and the raw data will be logged for analysis. (I also plan on a mode where the raw samples can be dumped).

Ultimately I'm hoping to implement a "smart" RPC, and be able to switch in/out some balance caps to keep the voltage near ideal. Yeah, American Rotary already implements something like that in their higher end series, but this is a DIY project.

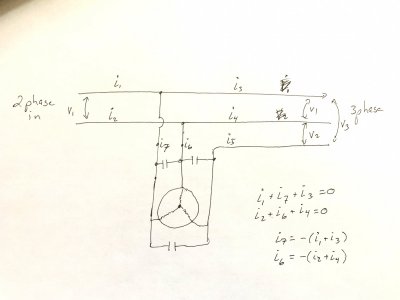

Here's an obligatory picture of my furnace transformer pretending to be a RPC. Note the potentiometer to allow me to vary the output a bit.

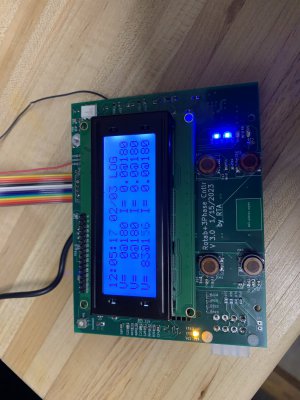

The board I'm working on. The blue cable is going off to my stepper (see the rotary table thread). The ribbon cable (bottom right of first pic) goes to a rotary encoder "knob" for user input. The top right connector with a couple of test leads/wires is the A/D inputs.

Front face of same:

Not too long ago I purchased a "project" VMC, one that will need plenty of TLC. It draws something like 60amps @ 240V three phase. That is not a small phase converter. My current phase converter uses a 20HP idler. I built a new shop in the last year, so I ran wire suitable for up to 125A (at single phase 240V) to the phase converter. So I should be able to expand my RPC by adding an idler.

I equipped my phase converter with voltage and amperage displays. But unless you are standing in front of the panel staring at the displays, they are of limited value. Certainly don't need to be trying to turn something on the big lathe while staring at the RPC. (My <5HP machines use VFDs, so only the big things require the RPC).

So in parallel with another microcontroller project, I've used a Raspberry Pi Pico and am working on a three phase logging tool. Using a 6 channel differential A/D converter and some isolation transformers I'm able to capture voltage and current on all three legs sampled at 1.041 ms (16 samples/cycle of 60Hz). Well, so far I've used a cheap furnace transformer as a bench test. Anyway, roughly every 1/2 second I'm getting a dump of voltage/current, phase and noise for all 6 channels. Goal is to use a Pico W to send the data wirelessly to a Raspbery Pi 4 B to capture along with a real-time timestamp. A simple web server on the RPI 4B can give stats, history, etc, etc. and the raw data will be logged for analysis. (I also plan on a mode where the raw samples can be dumped).

Ultimately I'm hoping to implement a "smart" RPC, and be able to switch in/out some balance caps to keep the voltage near ideal. Yeah, American Rotary already implements something like that in their higher end series, but this is a DIY project.

Here's an obligatory picture of my furnace transformer pretending to be a RPC. Note the potentiometer to allow me to vary the output a bit.

The board I'm working on. The blue cable is going off to my stepper (see the rotary table thread). The ribbon cable (bottom right of first pic) goes to a rotary encoder "knob" for user input. The top right connector with a couple of test leads/wires is the A/D inputs.

Front face of same:

Last edited: