- Joined

- Dec 18, 2019

- Messages

- 7,429

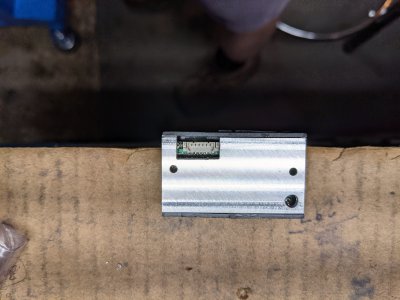

Due to some clumsiness and inattentiveness about 6 months ago (while setting up to single point thread) I managed to damage a rotary DRO on my mini-lathe. It still works, but won't tighten down properly. The display sort of pops up from the body of the unit, exposing the electronics to chips and cutting fluid. At this point the display isn't attached to the body. Obviously this is not good and I need to repair it. Trying to figure out a way to fix it. LMS is waiting for new units to come in, ie. they are out of stock and the kits have a lot of parts that I don't need to replace.

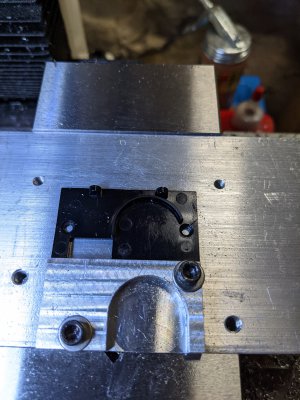

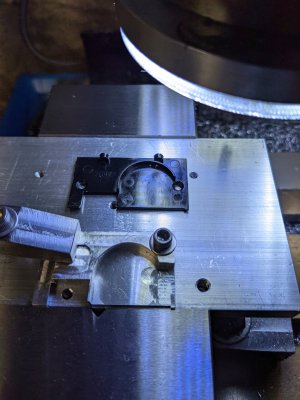

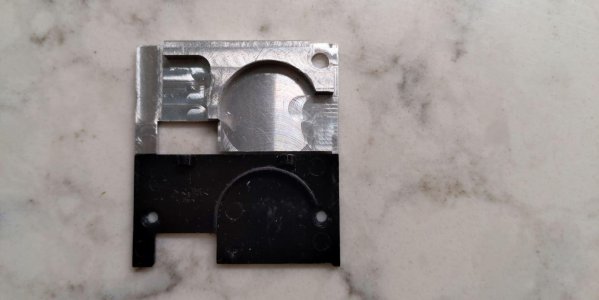

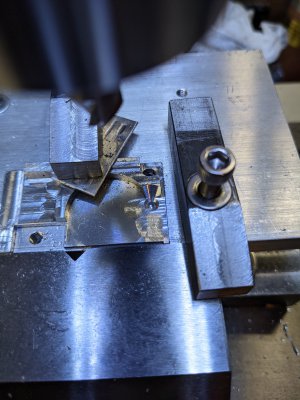

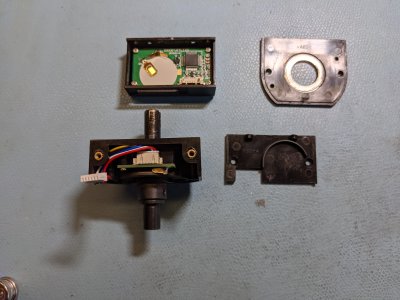

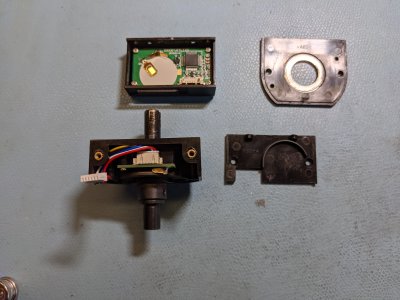

There are several things wrong. There are four parts 1) the display, the 2) display bottom plate, 3) the lower body and 4) the body cover plate. Parts 1 and 4 are mostly ok. The display bottom plate is bent and cracked near the left screw hole. When the DRO was clobbered, it pushed the right hand side brass insert in the lower body and enlarged the hole. The insert isn't captive - tightening the screw just pulls out the insert. The other insert moved, but it is still captive, at least for now. In the photo, the display is on the top left, the body cover plate the top right, the lower body is the bottom left, and the display bottom plate.

Could I epoxy the insert? Is there a better idea? Do I pull the insert then epoxy the hole and press the insert in?

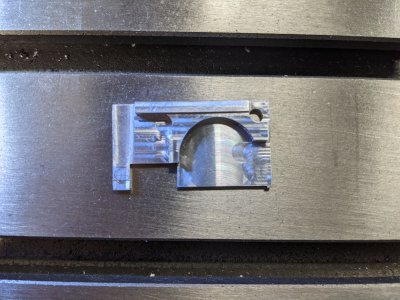

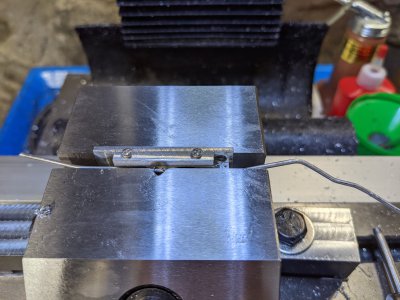

I could make a fixture plate to correctly locate the holes. For that matter, I could machine a new display bottom plate out of aluminum.

The bottom plate isn't flat anymore. There's a crack @ 2.9", right next to the hole.

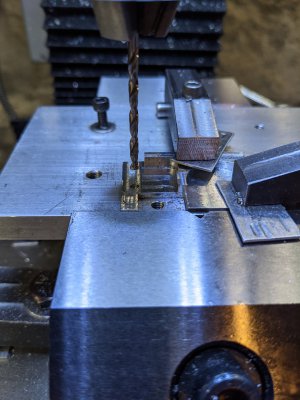

I can use the holes in the display bottom plate as hold downs. Looks like I can machine the cover out of 0.25" x 1.1" x 2" 6061. Will take a lot of operations, but it's doable. I'd use a boring head for the battery cut out (2032). The little ears on the display bottom plate need to be drilled. The original used little "wood screws" I would tap them instead, they are M2.

Any (better) ideas on how to rescue this poor thing? Thanks for any and all ideas.

There are several things wrong. There are four parts 1) the display, the 2) display bottom plate, 3) the lower body and 4) the body cover plate. Parts 1 and 4 are mostly ok. The display bottom plate is bent and cracked near the left screw hole. When the DRO was clobbered, it pushed the right hand side brass insert in the lower body and enlarged the hole. The insert isn't captive - tightening the screw just pulls out the insert. The other insert moved, but it is still captive, at least for now. In the photo, the display is on the top left, the body cover plate the top right, the lower body is the bottom left, and the display bottom plate.

Could I epoxy the insert? Is there a better idea? Do I pull the insert then epoxy the hole and press the insert in?

I could make a fixture plate to correctly locate the holes. For that matter, I could machine a new display bottom plate out of aluminum.

The bottom plate isn't flat anymore. There's a crack @ 2.9", right next to the hole.

I can use the holes in the display bottom plate as hold downs. Looks like I can machine the cover out of 0.25" x 1.1" x 2" 6061. Will take a lot of operations, but it's doable. I'd use a boring head for the battery cut out (2032). The little ears on the display bottom plate need to be drilled. The original used little "wood screws" I would tap them instead, they are M2.

Any (better) ideas on how to rescue this poor thing? Thanks for any and all ideas.