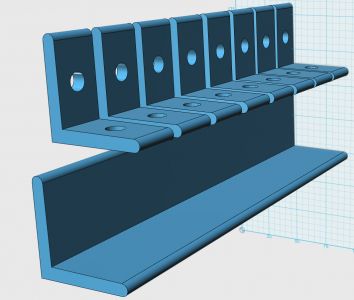

I have a 10-inch bar of angle Aluminum, 2" x 2" x 1/4" thick. I need to cut it into 8 pieces, each 0.995" +/- 0.005" wide. The rough cuts will be done on a bandsaw. The leaves are of course not quite perfectly parallel on both sides, but the two leaves are very perpendicular on their outside faces. I have considered facing the edges in the 4-jaw chuck on my lathe, and I have considered a couple of fixtures that would allow me to mill at least two at a time to the required width, but I am not quite satisfied with any of my ideas. The finished pieces will have a 3/8" hole right in the center of each face, so these could be used for attaching to a fixture.

Any good ideas out there?

Any good ideas out there?