- Joined

- Sep 4, 2012

- Messages

- 22

G'Day,

I haven't bragged too much yet about a Herless clone I dragged out of a skipbin. It's a variable speed head (2HP) and missing some parts, and other parts damaged.

Whilst I'm working on repairing the broken parts, I hoped someone can help me out with some dimensions, and maybe some photos of some parts I'm missing.

The Mill has metric axis screws, but all missing parts have imperial threads.

I am missing every single knob off the head - from other photos they appear to be black balls around 1" in diameter - is that correct? (I know they are 1/4"-20 threads except the spindle brake which is 3/8"-16)

Is the spindle brake knob a different diameter?if so, what size?

How is the spindle brake operated? (it appears to be something I'd turn, but mine is not moving) Does the spindle need to be turning to engage the brake? any other tips as to moving the spindle brake? (or warnings regarding operating it without power?)

The Quill handles are all missing:

The lever - I know it's 3/8"-16 thread - but what shaft diameter? length? Ball diameter?

The handle (the rotating one at the front)

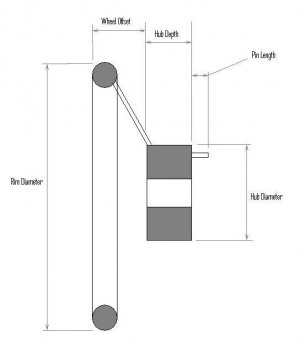

I know the bore diameter, but what is the depth of the hub? How deep s the handle (from back of hub, to front of rim) Rim diameter?

What is the length of the protruding pin?

The reversing knob... all I see is a small brass bush about 1/4" with a small threaded hole in it. The brass bush is nearly flush with the end of the shaft when "in", and protrudes around 3/16" to 1/4" when pulled out. What is the thread of the hole? (I suspect 12-32 or 10-32 but unsure since the taps aren't easily turning in)

What does the missing button/knob look like? - made of anything particlur? (plastic, brass, steel)

How is it retained (screw, or threaded shaft)?

How far should it come out when operated?

Is it spring loaded, or simply a sliding movement?

I've freed up the quill lock, and the micrometer depth stop. Found the Hi/Neutral/Lo back gear system can engage if I turn the spindle by hand

That's been all I've been able to figure out thus far - hopefully more functions will be operable once I get the motor running, but that will involve restoration of the damaged wiring, plus access to 3 phase outlet.

I'll be making a replacement knee handle soon, then working on repairing the snapped Y axis screw... most of the other repairs are fairly straight forward after those.

Many many thanks in advance for this information.

Des

Oz

I haven't bragged too much yet about a Herless clone I dragged out of a skipbin. It's a variable speed head (2HP) and missing some parts, and other parts damaged.

Whilst I'm working on repairing the broken parts, I hoped someone can help me out with some dimensions, and maybe some photos of some parts I'm missing.

The Mill has metric axis screws, but all missing parts have imperial threads.

I am missing every single knob off the head - from other photos they appear to be black balls around 1" in diameter - is that correct? (I know they are 1/4"-20 threads except the spindle brake which is 3/8"-16)

Is the spindle brake knob a different diameter?if so, what size?

How is the spindle brake operated? (it appears to be something I'd turn, but mine is not moving) Does the spindle need to be turning to engage the brake? any other tips as to moving the spindle brake? (or warnings regarding operating it without power?)

The Quill handles are all missing:

The lever - I know it's 3/8"-16 thread - but what shaft diameter? length? Ball diameter?

The handle (the rotating one at the front)

I know the bore diameter, but what is the depth of the hub? How deep s the handle (from back of hub, to front of rim) Rim diameter?

What is the length of the protruding pin?

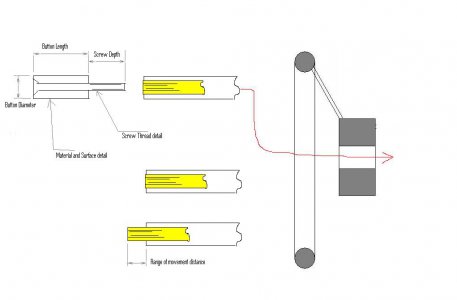

The reversing knob... all I see is a small brass bush about 1/4" with a small threaded hole in it. The brass bush is nearly flush with the end of the shaft when "in", and protrudes around 3/16" to 1/4" when pulled out. What is the thread of the hole? (I suspect 12-32 or 10-32 but unsure since the taps aren't easily turning in)

What does the missing button/knob look like? - made of anything particlur? (plastic, brass, steel)

How is it retained (screw, or threaded shaft)?

How far should it come out when operated?

Is it spring loaded, or simply a sliding movement?

I've freed up the quill lock, and the micrometer depth stop. Found the Hi/Neutral/Lo back gear system can engage if I turn the spindle by hand

That's been all I've been able to figure out thus far - hopefully more functions will be operable once I get the motor running, but that will involve restoration of the damaged wiring, plus access to 3 phase outlet.

I'll be making a replacement knee handle soon, then working on repairing the snapped Y axis screw... most of the other repairs are fairly straight forward after those.

Many many thanks in advance for this information.

Des

Oz