- Joined

- Jun 7, 2013

- Messages

- 10,450

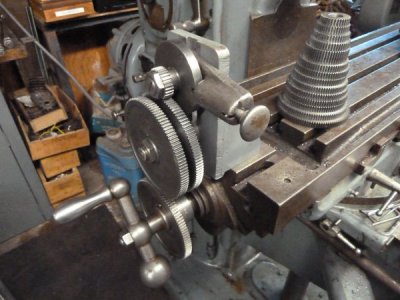

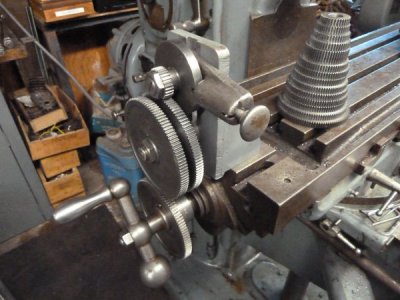

About 30 years or so ago, I acquired a B&S linear dividing unit to be used with the rack milling attachment; it laid around for all those years until I found information describing the attachment and the calculations for determining the change gears for it, with a list of change gears required and a chart of diametral and circular pitches, this was in a very old Machinery Magazine that came up online; mainly it was a tutorial of the use of continued fractions to determine gear ratios, using the B&S attachment as an example. Having that in hand, I spent about a week part time to make all the gear blanks and cutting the teeth, which were 24 DP and 3/8" wide; this amounted to 1007 teeth, not including a couple of mistakes due to indexing errors and misreading the number of divisions for one gear blank; 98 and 89 look pretty much the same upside down!

Here are some pics of the completed job, although I may have to make a taller bracket to mount the unit on the machine table so that there is sufficient slot height for all the gear combinations.

In the last pic, I show the rack milling attachment, I would like to find one for my machine, which would look a bit different than the one shown, it would have holes on top to fit the twin overarms of a #2 universal light type milling machine.

Here are some pics of the completed job, although I may have to make a taller bracket to mount the unit on the machine table so that there is sufficient slot height for all the gear combinations.

In the last pic, I show the rack milling attachment, I would like to find one for my machine, which would look a bit different than the one shown, it would have holes on top to fit the twin overarms of a #2 universal light type milling machine.