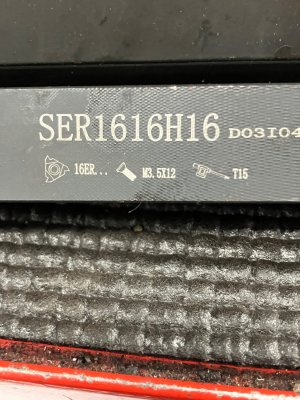

I ordered a set of thread, turning tool holders. When I receive them, the external tool holder has a insert. I am not familiar with.

Returning it is a bit of a hassle and it’s going to cost me nine bucks in shipping.

When I run the numbers on the box, it came in and the tool itself. It comes back with an insert like the one that is on the internal bar.

Maybe I just don’t know how to look up what I’m looking for but when I run the number on the tool and the insert number, it comes back with a three tipped indexable bit. Not the single point bit on this tool.

Is there any advantage ro this style?

I just assume get a box of inserts if possible vs the hassle of returning it.

Returning it is a bit of a hassle and it’s going to cost me nine bucks in shipping.

When I run the numbers on the box, it came in and the tool itself. It comes back with an insert like the one that is on the internal bar.

Maybe I just don’t know how to look up what I’m looking for but when I run the number on the tool and the insert number, it comes back with a three tipped indexable bit. Not the single point bit on this tool.

Is there any advantage ro this style?

I just assume get a box of inserts if possible vs the hassle of returning it.