- Joined

- Sep 29, 2017

- Messages

- 2,295

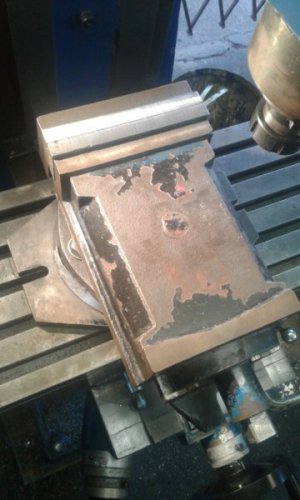

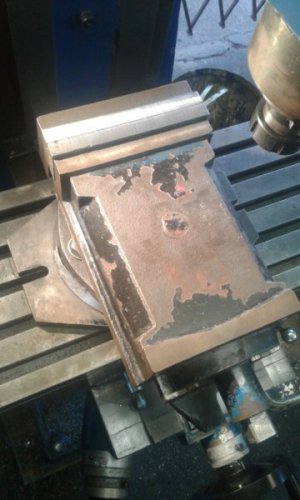

So this is the vice I got with my mill/drill and I finally got around to refurbish it.

As you can see it has a bit of drill damage,which I will fill up with JB weld and machine it down. It also has a bit too much play. But the main problem is it is not parallel with the mill bed. So I am going to sort that out.

I stripped it completely to see where the problem lies.

The screw and nut needed to be replaced.

I clamped both the top and bottom part to the bed and flycut those true to the bed.

I assebled the base and middle section and trammed the vice.

It looks good from one side to the other....way better than before.

I milled the jaw landing,replaced the jaw and squared that up too.

This is the first time I did ACME thread and I must say it went pretty well with the screw with the 15/16 - 5Tpi thread. The nut on the other hand gave me a bit of resistance. But that was mainly because of the small bore and I did not quite have the right internal boring bar,but it all worked out fine.

This is the final product comparison pic of that.

I went on to flycut,mill,skim every flat section true and parallel to the bed and to take out any extra play between the top part and bed section.

Lastley I milled the jaws true and square. And this is the final product.

Just need to make a spanner for it.

This took me a while,but it was all good fun. I want to repaint it,but the paint suppliers gave me a hefty price on oil resistant paint. I am not sure if I want to pay over $25 for a litre of hammerite paint. Any suggestions for oil resistant paint is welcome, I just don't know if what you guys have in the US and the rest of the world is available in SA. Thanks for watching.

Michael.

As you can see it has a bit of drill damage,which I will fill up with JB weld and machine it down. It also has a bit too much play. But the main problem is it is not parallel with the mill bed. So I am going to sort that out.

I stripped it completely to see where the problem lies.

The screw and nut needed to be replaced.

I clamped both the top and bottom part to the bed and flycut those true to the bed.

I assebled the base and middle section and trammed the vice.

It looks good from one side to the other....way better than before.

I milled the jaw landing,replaced the jaw and squared that up too.

This is the first time I did ACME thread and I must say it went pretty well with the screw with the 15/16 - 5Tpi thread. The nut on the other hand gave me a bit of resistance. But that was mainly because of the small bore and I did not quite have the right internal boring bar,but it all worked out fine.

This is the final product comparison pic of that.

I went on to flycut,mill,skim every flat section true and parallel to the bed and to take out any extra play between the top part and bed section.

Lastley I milled the jaws true and square. And this is the final product.

Just need to make a spanner for it.

This took me a while,but it was all good fun. I want to repaint it,but the paint suppliers gave me a hefty price on oil resistant paint. I am not sure if I want to pay over $25 for a litre of hammerite paint. Any suggestions for oil resistant paint is welcome, I just don't know if what you guys have in the US and the rest of the world is available in SA. Thanks for watching.

Michael.