- Joined

- Aug 22, 2012

- Messages

- 4,271

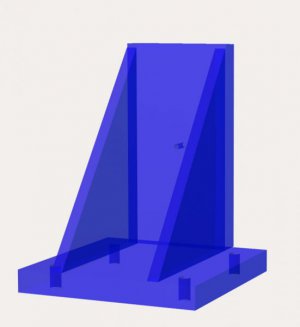

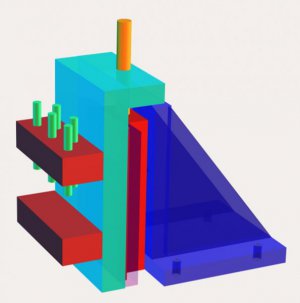

I will be making a couple of webbed angle plates from 12mm hot rolled steel.

They will be welded up with triangular webs.

I realise that the welding will distort them slightly.

Whats the consensus with getting them red hot in the furnace and soaking it for some minutes then allowing them to cool slowly as a means of removing any residual stress that may be in them.

Do you think its even necessary.

They will be faced in the lathe after this by Dave Gingery's method.

They will be welded up with triangular webs.

I realise that the welding will distort them slightly.

Whats the consensus with getting them red hot in the furnace and soaking it for some minutes then allowing them to cool slowly as a means of removing any residual stress that may be in them.

Do you think its even necessary.

They will be faced in the lathe after this by Dave Gingery's method.