- Joined

- Jul 2, 2022

- Messages

- 78

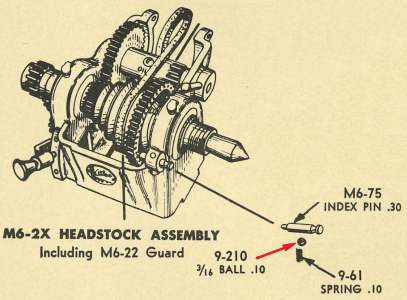

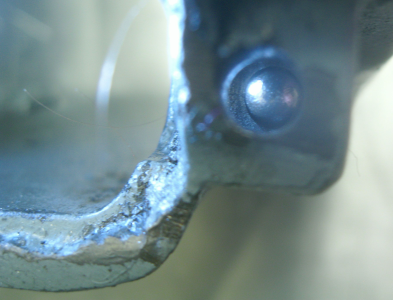

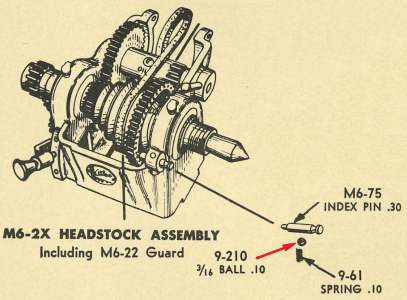

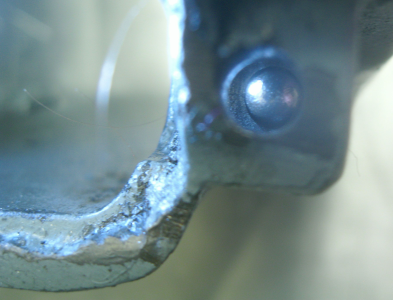

I have successfully removed a 3/16" 9-210 detent ball that was stuck hard below the surface of the blind hole it was in on my Atlas 618. This is the ball that rides against the underside of the M6-75 index pin that locks the spindle bull gear (back gear). I first tried soaking the hole and ball in penetrating oil overnight hoping that the spring behind the ball would push it out once the oil did its magic. No such luck. Pushing the ball inward to break it loose only pushed it inward without breaking it loose, and so I was successful only in moving it about 1/16" in the wrong direction. What worked was chucking up a 1/8" 2-flute carbide end mill in a cordless Dremel drill and milling material off the ball at the highest speed of the drill. At some point the ball broke loose and rotated a little bit but didn't come out. I then moved the cutter off-center to get the ball to rotate while removing material and it eventually got loose enough to come out.

The ball is .1875 diameter, but I found that the hole is called out .190/.187 on the Atlas factory drawing. That is too tight a fit, so I carefully drilled out the hole to .201 with a #7 drill. Now everybody is happy. Images below. Looks like the spring was home-made by a PO.

The ball is .1875 diameter, but I found that the hole is called out .190/.187 on the Atlas factory drawing. That is too tight a fit, so I carefully drilled out the hole to .201 with a #7 drill. Now everybody is happy. Images below. Looks like the spring was home-made by a PO.