- Joined

- Oct 31, 2016

- Messages

- 2,720

We throw the terms "register,""registered" and "registering"around and I think that I understand what it means.

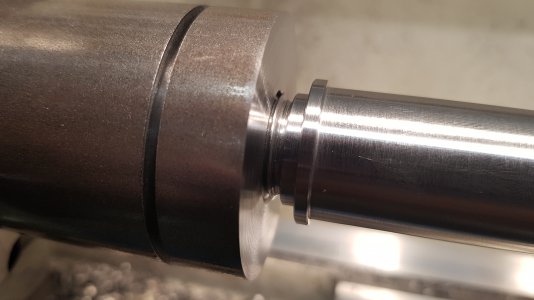

Right now I am making an adapter to mate a 4 jaw chuck I recently bought to fit the spindle on my lathe. The threads are slightly loose. I have a very, very tight fit on "A" in the picture below. So tight the that adapter really doesn't want to go up against "B" in the picture.

Would this mean that the adapter is registered on "A?" Should the adapter register on "A" and "B?" Or just on "B" with a slightly loose fit on "A?"

And how do we know when something is registered? I don't want to go any further with this project until I get this figured out.

I am probably using incorrect terminology here.

Right now I am making an adapter to mate a 4 jaw chuck I recently bought to fit the spindle on my lathe. The threads are slightly loose. I have a very, very tight fit on "A" in the picture below. So tight the that adapter really doesn't want to go up against "B" in the picture.

Would this mean that the adapter is registered on "A?" Should the adapter register on "A" and "B?" Or just on "B" with a slightly loose fit on "A?"

And how do we know when something is registered? I don't want to go any further with this project until I get this figured out.

I am probably using incorrect terminology here.