- Joined

- Jan 17, 2016

- Messages

- 71

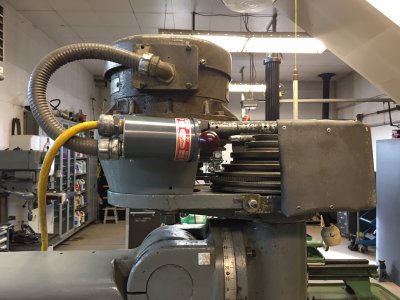

Hi... I'm a recent new member and I just bought a Millrite vertical mill. It was located in Ohio. I was looking to expand my metalworking capabilities in my home shop (retired electrician). Wanted a lathe or mill (most advice said lathe first) so I was looking mostly at lathes (lost a few due to beginners hesitation) and was gettin a little frustrated when I noticed the Millrite had appeared. Long story short, I went to look at it yesterday and bought it. It is in good overall shape, has the optional (factory) power table feed (the factory control for it has been replaced) and the optional "double swivel" ram to allow the head to be swung through compound angles. The factory front (cast) pulley guard must have broke at sometime and a homemade guard was installed (I'm going to TRY and find one). It also came with some tooling, vise, drill chuck and a extra (round wheel) that can be used in place of the factory handle to raise/lower the knee faster. It has the factory 3 phase motor, so I will have to gat a VFD for it (it was hooked up to one at the sellers shop). I was able to hear it rin and see it cut...it seemed smooth and quiet.

I hadn't thought of getting a knee mill at first (was thinking most decent "Bridgeport" style mills were too big and expensive) and was looking at some Precision Matthews mills (PM-727) since Quality Machine Tools is close to me. I was able to get the Millrite for just a little more.

Now I need any advice on setting it up and dialing it in when I get it home.

Here's a few pictures:

I hadn't thought of getting a knee mill at first (was thinking most decent "Bridgeport" style mills were too big and expensive) and was looking at some Precision Matthews mills (PM-727) since Quality Machine Tools is close to me. I was able to get the Millrite for just a little more.

Now I need any advice on setting it up and dialing it in when I get it home.

Here's a few pictures:

Last edited: