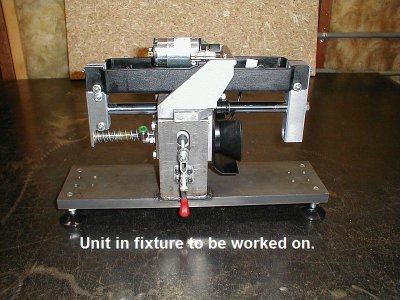

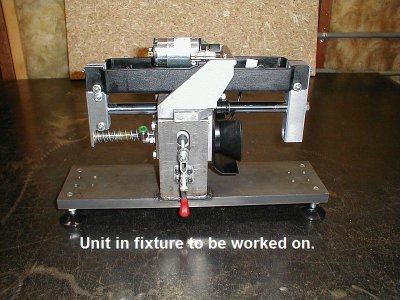

A while back a customer came in needing a fixture or stand to hold a component out of a coffee machine for rebuilding.

Also needed a way to test it before sending back into service. The component gets rebuilt after every 100,000 cups of

coffee made whether it needs it or not I made a fixture to hold the unit to make the rebuild easier. Part of the rebuild

I made a fixture to hold the unit to make the rebuild easier. Part of the rebuild

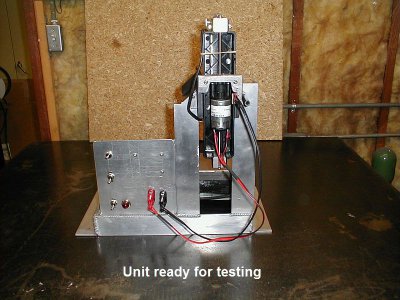

was replacing a 24 volt dc motor and a limit switch as well as a couple of bearings and this was done every time. Next they

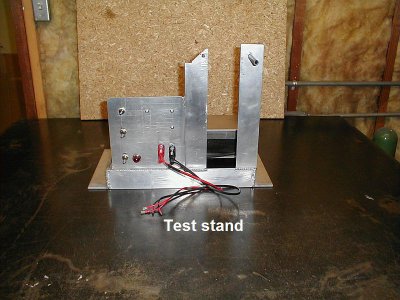

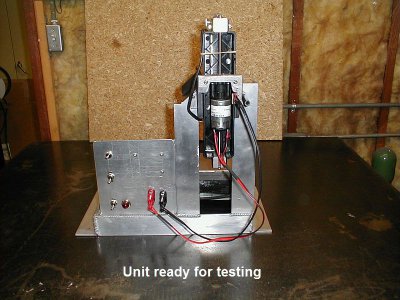

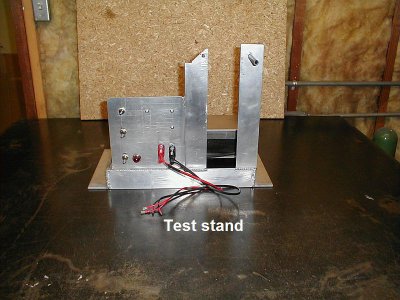

needed a way of testing the unit to make sure it was in working order and the limit switch tripped correctly. Can't remember

how it worked exactly but the limit switch controlled two functions via a couple of bumps on the slide that the motor ran.

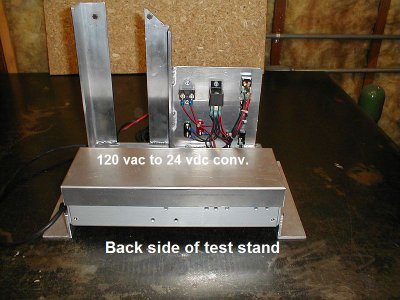

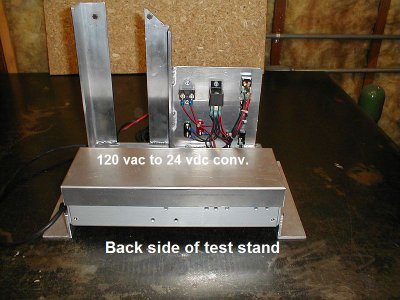

The test stand consisted of a 120 vac to 24 vdc converter which allowed the motor and switch function to be tested.

Work good and a couple of months later wanted another one made. Would have been nice to build them at the same time

Dave

Also needed a way to test it before sending back into service. The component gets rebuilt after every 100,000 cups of

coffee made whether it needs it or not

was replacing a 24 volt dc motor and a limit switch as well as a couple of bearings and this was done every time. Next they

needed a way of testing the unit to make sure it was in working order and the limit switch tripped correctly. Can't remember

how it worked exactly but the limit switch controlled two functions via a couple of bumps on the slide that the motor ran.

The test stand consisted of a 120 vac to 24 vdc converter which allowed the motor and switch function to be tested.

Work good and a couple of months later wanted another one made. Would have been nice to build them at the same time

Dave