- Joined

- Mar 18, 2023

- Messages

- 19

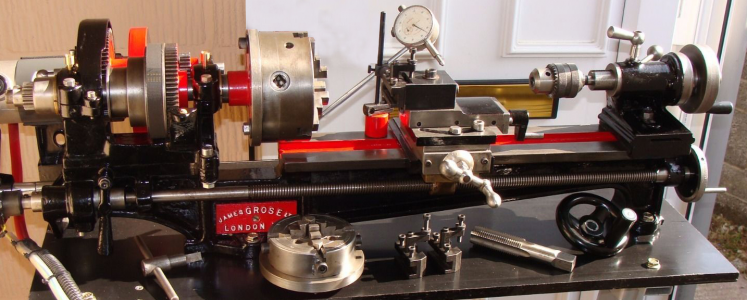

So here we go, I have just purchased for a grand total of £190 A Randa lathe. It seemed a good price, though obviously I wasn't expecting it to be in tip top condition. I have never restored a lathe before, So I will be very open to suggestions as to how best proceed.

So here she is, as you can see, the lathe has been fitted to a pretty solid metal cradle: A .75KW (1HP?) 3 phase motor was included with a pretty convoluted belt drive.

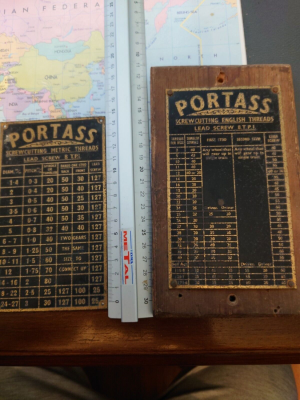

The lathe itself is stamped as a Randa, though as far as i can work out, it is a rebranded Portass S.

According to the seller, he inherited it from an Uncle and has not done much with it over the last few years.

I am guesstimating the lathe is post war and that the cradle is a similar age. The cradle is branded Crosby, Preston

I am guessing the age of the cradle based on what looks like a bakelite switch and also this Singer sowing motors badge found on the rear:

![20230318_163338[1].jpg 20230318_163338[1].jpg](https://www.hobby-machinist.com/data/attachments/398/398974-66e382dbe161d8d3f26d3544632299fc.jpg)

The Singer motor has gone, replaced with a more modern Leroy Somer 3 phase motor:

The motor is being driven by a Eurotherm 1 phase to 3 phase programable VFD. Speed can be adjusted on the front panel of the VFD and a quick read through of the manual tells me it has i/o connections for various controls which might come in handy later.

I will place a follow up post with some information on the included accessories.

Condition wise, it's all a bit tired looking. There seems to be some play in the feeds, not terrible in the crosslide, the handle not matching the rest of the machine (a repair perhaps?) The lead screw on the other hand has a lot of play. Probably down to a badly worn nut

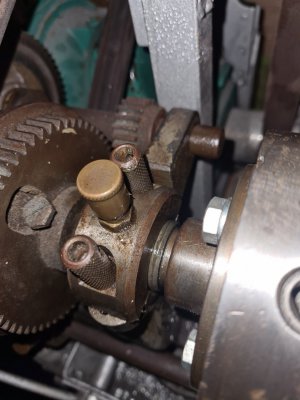

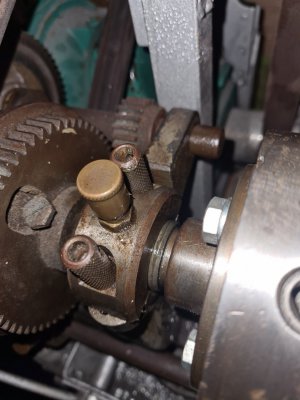

The Headstock seems pretty solid, there was some lateral play there, but I managed to adjust that out, not sure how best to measure the runout though. Will work on this. What I do need to do is take it apart for a right good clean. The previous owner appears to have filled the oil reservoirs with grease which I know is not right, hopefully it has not been run very long like this, but clearly it will need cleaned.

There has been a repair on the headstock at some point. I am assuming the case broke at some point close to the chuck. It has been repaired

So my first question. I plan to remove the lathe from it's cradle for a complete disassembly, clean and probably paint. I want to use the correct oil for reassembly, what lubricants should I be using for the headstock bushings and latheways etc?

So here she is, as you can see, the lathe has been fitted to a pretty solid metal cradle: A .75KW (1HP?) 3 phase motor was included with a pretty convoluted belt drive.

The lathe itself is stamped as a Randa, though as far as i can work out, it is a rebranded Portass S.

According to the seller, he inherited it from an Uncle and has not done much with it over the last few years.

I am guesstimating the lathe is post war and that the cradle is a similar age. The cradle is branded Crosby, Preston

I am guessing the age of the cradle based on what looks like a bakelite switch and also this Singer sowing motors badge found on the rear:

![20230318_163338[1].jpg 20230318_163338[1].jpg](https://www.hobby-machinist.com/data/attachments/398/398974-66e382dbe161d8d3f26d3544632299fc.jpg)

The Singer motor has gone, replaced with a more modern Leroy Somer 3 phase motor:

The motor is being driven by a Eurotherm 1 phase to 3 phase programable VFD. Speed can be adjusted on the front panel of the VFD and a quick read through of the manual tells me it has i/o connections for various controls which might come in handy later.

I will place a follow up post with some information on the included accessories.

Condition wise, it's all a bit tired looking. There seems to be some play in the feeds, not terrible in the crosslide, the handle not matching the rest of the machine (a repair perhaps?) The lead screw on the other hand has a lot of play. Probably down to a badly worn nut

The Headstock seems pretty solid, there was some lateral play there, but I managed to adjust that out, not sure how best to measure the runout though. Will work on this. What I do need to do is take it apart for a right good clean. The previous owner appears to have filled the oil reservoirs with grease which I know is not right, hopefully it has not been run very long like this, but clearly it will need cleaned.

There has been a repair on the headstock at some point. I am assuming the case broke at some point close to the chuck. It has been repaired

So my first question. I plan to remove the lathe from it's cradle for a complete disassembly, clean and probably paint. I want to use the correct oil for reassembly, what lubricants should I be using for the headstock bushings and latheways etc?