- Joined

- Jan 20, 2018

- Messages

- 5,900

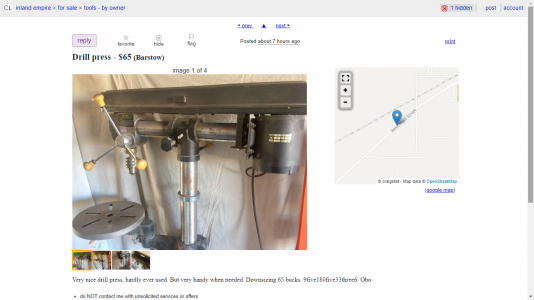

Drill press - tools - by owner - sale

Very nice drill press, hardly ever used. But very handy when needed. Downsizing 65 bucks....

inlandempire.craigslist.org

I don't get those. Designed to loose rigidity? Ok for plywood I suppose.

Drill press - tools - by owner - sale

Very nice drill press, hardly ever used. But very handy when needed. Downsizing 65 bucks....inlandempire.craigslist.org

View attachment 337666

While I can appreciate the lust for iron by the ton, I’m curious if you have a specific job in mind for this? I’m new to the radial drill press world and might not have thought the whole thing through as to ridigity. But I am finding the ability to wrangle large pieces onto the drill press a big plus. As a hobbyist it’s hard to find a radial arm drill that has that stout construction scaled down. I guess thats why most seem to use their mill instead.If I only had some room...

View attachment 337673

Where a radial drill excels is to do holes waaaay out from the supports. A typical radial drill will drill a hole 20-22" from the column. Most mills (including a bridgeport #1) are limited to 16-18 inches maximum.

Super rigid support isn't required. It is only suitable for drilling and tapping, and most can only do a 3/4" standard drill, or a 1.5" annular cutter.

I share the sickness in almost the same way. But I only have 1/3 the room. I had been struggling with my old HD HF DP benchtop. Along came a Rockwell UniDrill a fellow member here was wanting rid of. It was right in my price range and looked to be in good shape. Lots of cast iron with a huge benchtop base. I’ve been working my way through it and in looking for info on it a link came up to a discussion on the not so friendly site. Of course they trashed it but I guess they had some points. I just did some 1/2” holes in 3/8” thick steel today and it did fine. It has a 15” varidrive head and my problem with it is it’s got the 1750rpm motor on it that goes from 450 to 4,700rpm! It has on the same dial for a 1050rpm motor 200 to 3100rpm which still kinda seems fast for steel.incorrect quotes... answer for @C-Bag

I have only had a chance to use one one time but have seen a huge one that was used in the manufacture of very large printing presses. The one I used had really nice rpm range, super smooth action and was easy to use even for "small" parts. I used it for some catwalk parts and just for a few holes but it was quiet, easy to bring into action and precise. Great auto down feed and rigidity that made a mockery of a 3/4" hole in steel. Yea, big and precise. I would use it for a lot but would need a BIG shop to justify it. Compare that to a shaper, which has a nostalgic draw for me but would pretty much sit unused. I do use my mill as a drill press but it won't do a 1.5" Hole and be happy about it. I use those size drills on my lathe often, usually and the most efficient way to loose material before using a boring operation because I can't run a 3" drill

also, I am a machinery junkie and I perhaps enjoy and value manual precision machinery which can make and has made other amazing machines. I don't have interest in additive machining or really want CNC equipment. I think much to due to nostalgia. I'm not judging, I know I'm being silly but I find a machine like that heart warming and fascinating.

on the other hand, the small woodworking radial would likely not be very good at even making a 1/2" hole in a steel part since the downforce required would flex that a lot. For me it wouldn't really have utility. I do use my Taiwanese drill press a lot for small to medium holes (up to 1/2" or so). I gave a gear head solberga drill press to a friend because it took up to much space. I do get to use it occasionally and wish I would have had room for it. It's a sickness for sure.