- Joined

- Feb 2, 2014

- Messages

- 1,221

My friend stopped around the other day with a present for me. It was a gear motor with a rack from a tread mill that is used to raise and lower the bed. He said he had no use for it and that I could possibly make something useful from it. Well I already had one exactly like it from a tread mill I had salvaged and just couldn't bring my self to throw it away so now I have two of them but what to make?

The rack only gives about 4" of travel so that is the first thing that has to be modified.

I had some 1/2" steel square stock about 15" long so I will start there for a new rack. The width of the material was cut down to 0.375 to fit the gear box guide flange and then holes were drilled in the ends in order to hold it on the mill table.

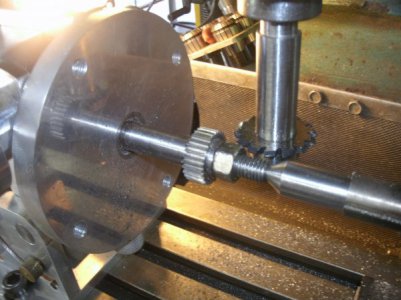

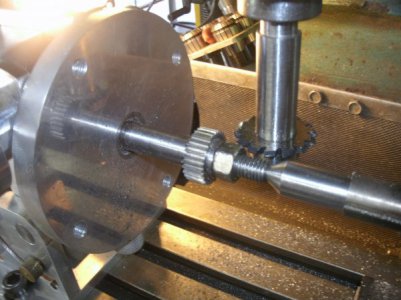

This shows cutting the teeth in the new rack.

I used a Module 1 metric cutter with my 90 degree head.

104 teeth and about 13" long.

The teeth on the original gear motor shaft were cut down to 0.625 to accept the new metric gear.

I had no good way of measuring the distance from the center of the gear motor shaft to the new rack teeth so I decided to make the new pinion gear a little larger than I thought I needed. There is no good way to adjust the rack for backlash as all the sizes are fixed. My reasoning was if the new rack wouldn't fit from being too tight then I could take some material off the bottom of it but if it was too loose I would have to remake the pinion gear.

Making the 29 tooth pinion gear to press on to the gear motor shaft.

The spacing ended up almost perfect with just a little bit of hand filing to fit.

I have 10.5" of travel that can be opened up to 12" if needed.

The rack moves at 20 inches a minute.

Ok so now I have a gear motor with a rack of some length ready for a project to make.

But that is the problem just what do I use it for?

I need your suggestions and ideas.

Thanks for looking

Ray

The rack only gives about 4" of travel so that is the first thing that has to be modified.

I had some 1/2" steel square stock about 15" long so I will start there for a new rack. The width of the material was cut down to 0.375 to fit the gear box guide flange and then holes were drilled in the ends in order to hold it on the mill table.

This shows cutting the teeth in the new rack.

I used a Module 1 metric cutter with my 90 degree head.

104 teeth and about 13" long.

The teeth on the original gear motor shaft were cut down to 0.625 to accept the new metric gear.

I had no good way of measuring the distance from the center of the gear motor shaft to the new rack teeth so I decided to make the new pinion gear a little larger than I thought I needed. There is no good way to adjust the rack for backlash as all the sizes are fixed. My reasoning was if the new rack wouldn't fit from being too tight then I could take some material off the bottom of it but if it was too loose I would have to remake the pinion gear.

Making the 29 tooth pinion gear to press on to the gear motor shaft.

The spacing ended up almost perfect with just a little bit of hand filing to fit.

I have 10.5" of travel that can be opened up to 12" if needed.

The rack moves at 20 inches a minute.

Ok so now I have a gear motor with a rack of some length ready for a project to make.

But that is the problem just what do I use it for?

I need your suggestions and ideas.

Thanks for looking

Ray