- Joined

- Sep 22, 2019

- Messages

- 89

As indicated in other threads, I bored out the upper end of my PM-833T's spindle socket so it would accept my Interstate collets.

It was pointed out that the threaded end of an R8 insert is precision ground. The explication being there is a tight fit between the insert and the spindle. This is presumably to counteract insert deflection under load.

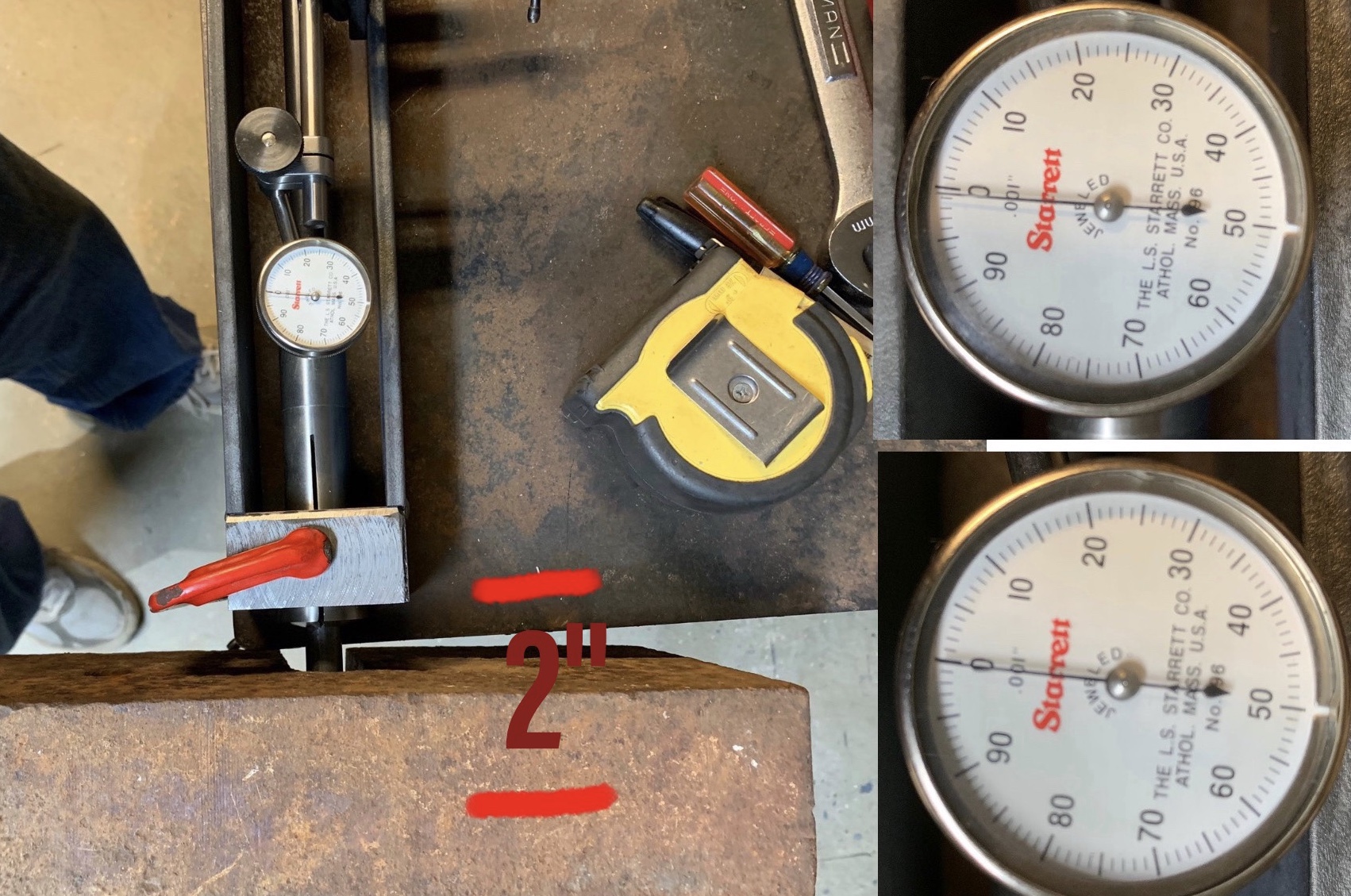

As pictured below I made a devise to measure R8 insert deflection under load. The measured deflection was .00075" for torques ranging from 88 inch pounds to 946 inch pounds. The torque was created by placing a 44 pound weight on a half inch rod secured in an R8 collet.

Varying the torque had no affect on the deflection. One explanation is that any load settled the apparatus, not the collet, causing an initial deflection. If this is the case, it could be argued that loads in the range tested result in no deflection of the insert.

If the deflection is a result of collet movement then a wide range of loads result in a deflection of .00075".

It was pointed out that the threaded end of an R8 insert is precision ground. The explication being there is a tight fit between the insert and the spindle. This is presumably to counteract insert deflection under load.

As pictured below I made a devise to measure R8 insert deflection under load. The measured deflection was .00075" for torques ranging from 88 inch pounds to 946 inch pounds. The torque was created by placing a 44 pound weight on a half inch rod secured in an R8 collet.

Varying the torque had no affect on the deflection. One explanation is that any load settled the apparatus, not the collet, causing an initial deflection. If this is the case, it could be argued that loads in the range tested result in no deflection of the insert.

If the deflection is a result of collet movement then a wide range of loads result in a deflection of .00075".