- Joined

- Aug 20, 2017

- Messages

- 31

I have a Bolton 1337G lathe, which research indicates is essentially the same machine as a PM-1340 except that the Bolton has a "closed" gear box while the PM is "open." In practical terms, I think this mainly means there are not as many gear choices on the Bolton. No big surprise there. So I need to make a stud with a 28tpi thread, and much to my surprise, my brand-new, sooper-dooper lathe won't do it.  Seriously???

Seriously???

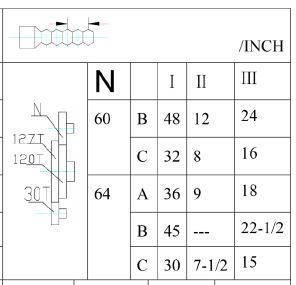

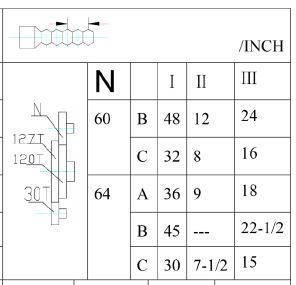

Here's a picture of the thread chart from the manual:

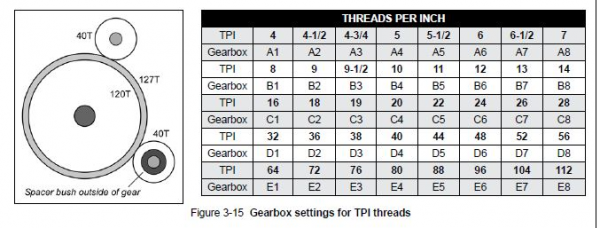

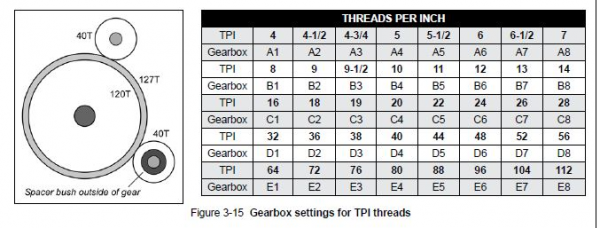

Yep -- 28tpi just isn't one of the options. Contrast this with the chart from the PM machine:

I'm guessing I could probably get the thread I need by using some different change gears. Kind of defeats the purpose of the quick-change gearbox, but OK. So then I start trying to figure out gear ratios and such, which was easy enough on my previous pre-quick-change lathe, and discover that the arithmetic doesn't really work anymore...

So can anyone tell me what I might need (or offer some insight as to how I can figure out what I need) to accomplish what should be a fairly straightforward task?

Here's a picture of the thread chart from the manual:

Yep -- 28tpi just isn't one of the options. Contrast this with the chart from the PM machine:

I'm guessing I could probably get the thread I need by using some different change gears. Kind of defeats the purpose of the quick-change gearbox, but OK. So then I start trying to figure out gear ratios and such, which was easy enough on my previous pre-quick-change lathe, and discover that the arithmetic doesn't really work anymore...

So can anyone tell me what I might need (or offer some insight as to how I can figure out what I need) to accomplish what should be a fairly straightforward task?