- Joined

- May 7, 2014

- Messages

- 776

Hi everyone, Looking to dialog some about the recent project w/ my Son. We moved on from his Axe project and onto a full Katana sword. These are all about learning... basically our "hello world" first jobs. all feedback welcome.

First axe: My experience w/ 1045 in the past was that we had a heck of a time with it!! For the Axe project we took to Annealing the 1045 which made it so soft you could bend it (1/4 HR plate) over your knee. Thus cutting it was a breeze! Clean crisp cuts. (pics below).

This time: Making a Katana sword- Our first long object! We wanted to see if we could be like the big-boys and just take 1045 and run a CNC program upon it. With an Anneal process we run the risk of warping and honestly, we just felt we should be able to mill this stuff on a beefy 30taper Supermax YMC setup??

The real sword will be out of 1090/1095... So that is why the setup Q's here.

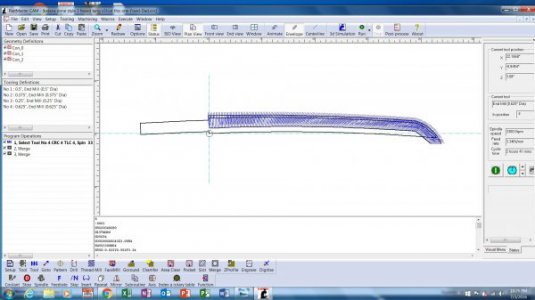

Here are the details. (pics below).

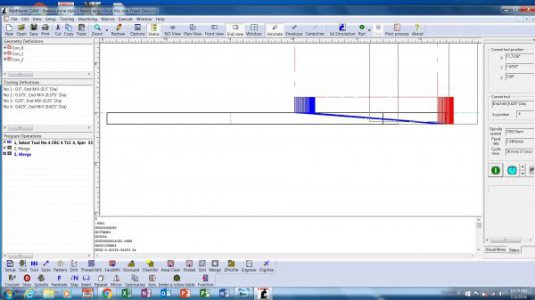

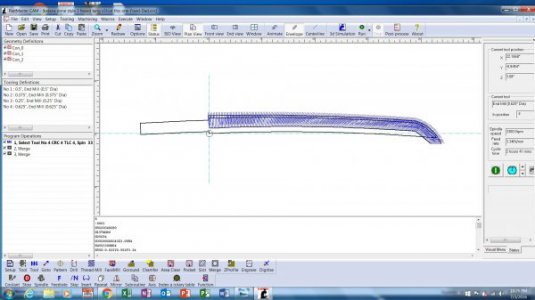

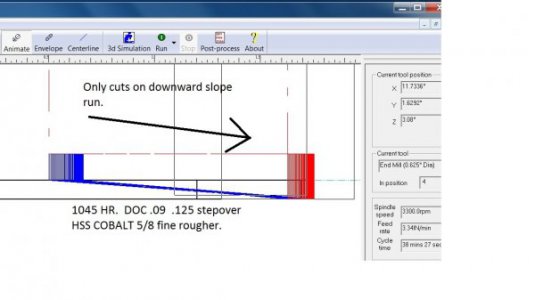

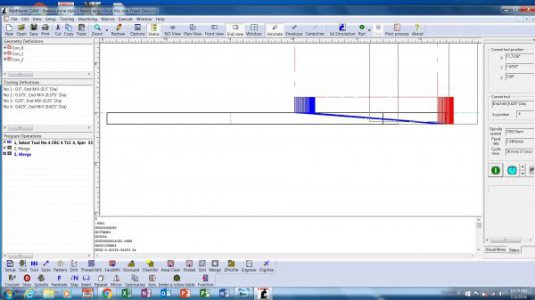

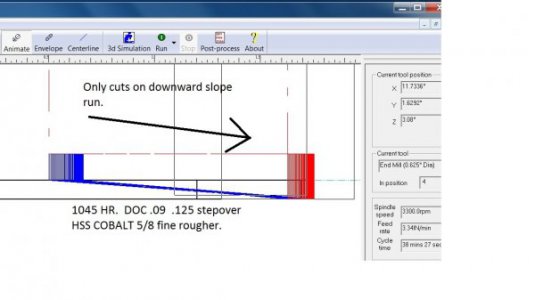

- Cutter- 5/8 HSS-Cobalt, Running .125 stepover, and 0 to .09 DOC on a slope cut. (see pics). This run is cutting down the blade.

-RPM SFM was experimented with G-wizard pushing the original values and range. RPM 400-500RPM. SFM 2.5 to 5.0 (3.34 per wizard). clockwise rotation. Only cuts on the down slope run. (see pics).

-Overall, the cutter wear became excessive on the bottom. To much rubbing. Corners are OK and it even feels fairly sharp on the edge. Towards the end of the long run, it would chatter rather hard at full DOC.

- The pic below shows it is chewed and a really ugly cut compared to the axe we did. (annlealed).

What I am wondering- I'm considering just going back to just Annealing the swords. It's a way to save cutters, and speed thru the job.... But- It just seemed that we should be able to cut this 1045 w/o a lot of issues and fuss every time.

My own thoughts:

-Should I omit the rubbing down force cutting from the Z0 top point to the .09 DOC. (called a merge job in DolphinCAM.) Wondering if I should start on the .09 DOC off the far edge and cut up to the 0 point??

- Go to conventional -vs- Climb?

-Carbide in the past just breaks unless the work is super super rigid for my newbie experience.

- Or just put the 1045 on 1095 into the oven and run the Anneals.

- Am I taking to thin a cut? Should I up the stepover? or run this in 2 passes (at a total of 2.5 hours).

- Maybe I should be trying a Carbide these days?

Some pics:

Thanks everyone. HAPPY 4th!

Jeff and Mitch.

First axe: My experience w/ 1045 in the past was that we had a heck of a time with it!! For the Axe project we took to Annealing the 1045 which made it so soft you could bend it (1/4 HR plate) over your knee. Thus cutting it was a breeze! Clean crisp cuts. (pics below).

This time: Making a Katana sword- Our first long object! We wanted to see if we could be like the big-boys and just take 1045 and run a CNC program upon it. With an Anneal process we run the risk of warping and honestly, we just felt we should be able to mill this stuff on a beefy 30taper Supermax YMC setup??

The real sword will be out of 1090/1095... So that is why the setup Q's here.

Here are the details. (pics below).

- Cutter- 5/8 HSS-Cobalt, Running .125 stepover, and 0 to .09 DOC on a slope cut. (see pics). This run is cutting down the blade.

-RPM SFM was experimented with G-wizard pushing the original values and range. RPM 400-500RPM. SFM 2.5 to 5.0 (3.34 per wizard). clockwise rotation. Only cuts on the down slope run. (see pics).

-Overall, the cutter wear became excessive on the bottom. To much rubbing. Corners are OK and it even feels fairly sharp on the edge. Towards the end of the long run, it would chatter rather hard at full DOC.

- The pic below shows it is chewed and a really ugly cut compared to the axe we did. (annlealed).

What I am wondering- I'm considering just going back to just Annealing the swords. It's a way to save cutters, and speed thru the job.... But- It just seemed that we should be able to cut this 1045 w/o a lot of issues and fuss every time.

My own thoughts:

-Should I omit the rubbing down force cutting from the Z0 top point to the .09 DOC. (called a merge job in DolphinCAM.) Wondering if I should start on the .09 DOC off the far edge and cut up to the 0 point??

- Go to conventional -vs- Climb?

-Carbide in the past just breaks unless the work is super super rigid for my newbie experience.

- Or just put the 1045 on 1095 into the oven and run the Anneals.

- Am I taking to thin a cut? Should I up the stepover? or run this in 2 passes (at a total of 2.5 hours).

- Maybe I should be trying a Carbide these days?

Some pics:

Thanks everyone. HAPPY 4th!

Jeff and Mitch.