My son and i are rebuilding an old Briggs &b Stratton 6s engine. It has a cast iron one piece block and cylinder. We pulled the head off to find rust and pitting where the head / gasket / block mate. I used my Taig mill to take a light cut on the head - no problem. The block / cylinder casting was another matter, given its size (too tall to fit between the mill table and the headstock).

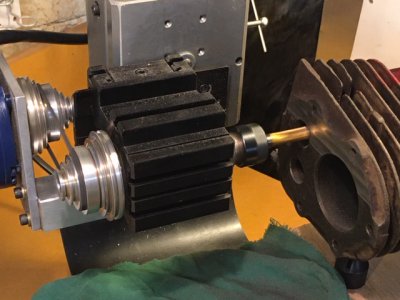

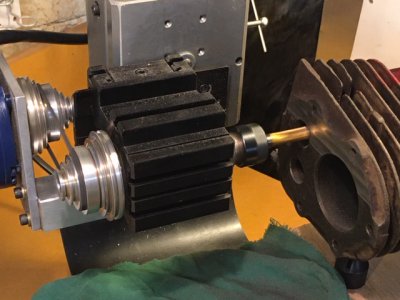

So, i pulled the headstock off the mill and rotated it horizontally, then clamped the engine casting to the table and trammed it all in. I took the cuts in the z axis instead of the x axis. It worked just fine and only took about 20 minutes to rotate the headstock and dial it in.

I'm still learning a lot, but i really like this little mill.

So, i pulled the headstock off the mill and rotated it horizontally, then clamped the engine casting to the table and trammed it all in. I took the cuts in the z axis instead of the x axis. It worked just fine and only took about 20 minutes to rotate the headstock and dial it in.

I'm still learning a lot, but i really like this little mill.