- Joined

- Dec 10, 2016

- Messages

- 20

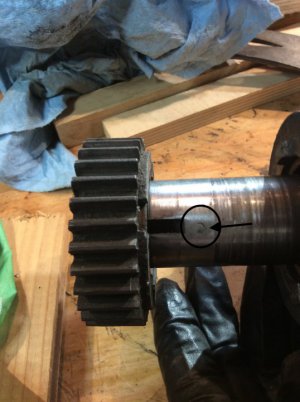

Did find a discussion here some time back about this pin on the headstock spindle. Failed to Bookmark so have to ask the question. Have taken apart a 10D to replace broken/brazed & missing parts. Found this pin and it would neither screw out or be pulled out after using fluids. Ended up breaking it and gently filed to the shaft. Question 1. is it needed? 2. purpose? 3. should the broken bit be drilled out and replaced?

Suggestions/comments appreciated. Thanks, Frank

Suggestions/comments appreciated. Thanks, Frank