- Joined

- Feb 2, 2013

- Messages

- 3,916

Hello Again!

i have a customer in a panic

their Mettler Toledo 90* conveyor needed a pulley, so i decided to make one from scratch.

i made the pulley mainly because MT is in Ohio and also because right now is not fast enough for this fickle customer!

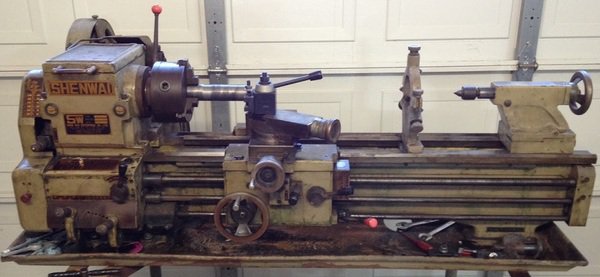

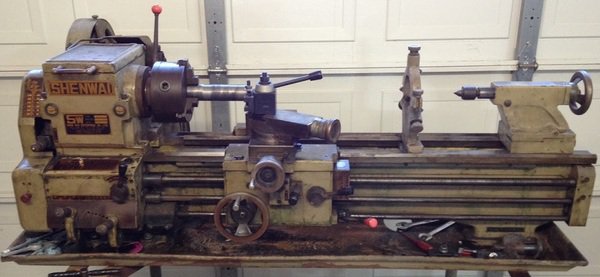

i first used my Shenwai SW900B lathe,

to turn down a 2.250" pulley blank from some 3"- 6061 aluminum rod that i had in stock.

i drilled the center hole out to 3/4", then bored the pulley out to .873" and created a .080"step for bearing retention.

i ground a 3/8" radius form turning tool to make a half round track

I used a R6-2RS bearing (.375"id x .875" od x .2812" wide), just like the factory assembly

in the pictures, the right pulley's are the OEM, you can see the wear upon closer inspection especially in the last picture

the worn pulley (below right) would no longer track a long round transmission belt, so it had to go!

my pulleys' shoulder came out a bit thinner than the OEM, a mistake in plunge on my part.

i don't think it to be detrimental to the overall performance- sometimes right now is right!

every day is a new game in my industry!

thanks for looking!

i have a customer in a panic

their Mettler Toledo 90* conveyor needed a pulley, so i decided to make one from scratch.

i made the pulley mainly because MT is in Ohio and also because right now is not fast enough for this fickle customer!

i first used my Shenwai SW900B lathe,

to turn down a 2.250" pulley blank from some 3"- 6061 aluminum rod that i had in stock.

i drilled the center hole out to 3/4", then bored the pulley out to .873" and created a .080"step for bearing retention.

i ground a 3/8" radius form turning tool to make a half round track

I used a R6-2RS bearing (.375"id x .875" od x .2812" wide), just like the factory assembly

in the pictures, the right pulley's are the OEM, you can see the wear upon closer inspection especially in the last picture

the worn pulley (below right) would no longer track a long round transmission belt, so it had to go!

my pulleys' shoulder came out a bit thinner than the OEM, a mistake in plunge on my part.

i don't think it to be detrimental to the overall performance- sometimes right now is right!

every day is a new game in my industry!

thanks for looking!

Last edited:

Steve Shannon

Steve Shannon