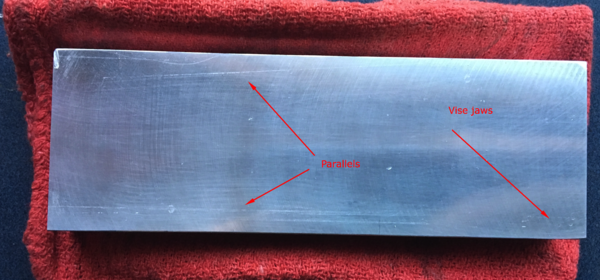

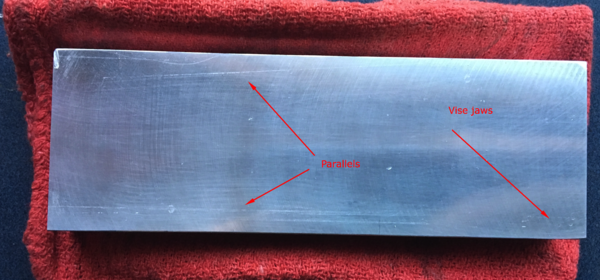

@mikey that is exactly the process I was doing (

although your explanation has been the clearest I've seen on this subject so far), the marring is happening when I'm hammering the piece into place on the vise. When I have two parallels under the reference surface, the front parallel is loose until I really mash on the workpiece with a deadblow hammer (

made extra difficult because my mill is tiny). Further, when you say 'lightly tighten the vise and tap with hammer', this doesn't work. When I fully tighten the vise the front side lifts - my vise is really a glorified drill press unit. I suspect the only way to get past that is to get me a decent vise.

The card stock trick might help, though, given that I have to mash it - worth a shot.

Also lol at wire edm. When I was in college, we did a tour of a plant doing wire edm, super cool stuff. Massively outside the capabilities of my humble home shop, however.

If there's gonna be another large machine, it'll be a surface grinder.