Hi

@sakumar

I have spent a lot of time with my gibs on the PM940M. I am not complaining, but here are some of my thoughts for you.

Yes, pushing in on the larger end provides tightening. The screw on the small end is for clamping it in place after moving the gib. However, if you leave it loose, or remove the gib screws and run the saddle along the ways then the gib will slide back and forth and can even get very tight. So after adjusting the gib with the screws always tighten the screws on both ends to hold the gib in place. Sure enough if you do not clamp the gib then the backlash can be different in the two directions!

You do not want the clamping screw to pinch the end of the gib into the ways. This is especially a hazard at the small gib end. If so this is applying lots of pressure at this one point, not a gib function at all as all .... the drag/friction is at only one end/point along the gib!

Yes, I found that if you adjust the gib too tight then the backlash can increases .. and it can increase significantly. If you tighten it too much it is equivalent to applying a lock. This backlash is a function of the load being driven by the motor etc. The drive load (motor coupling, bearings, lead screw itself, ball nut, gib, etc) tends to cause the lead screw to act like a spring being wound rather than resulting in motion of the saddle... when this drive load is heavier the backlash increases. I found that my ways, Y-axis, are not parallel, resulting in the gib being tighter at the wide area... and so the backlash increases at the wide position along the ways simply because the gib is too tight (increased load). I am still studying this in my spare time and trying to fix it by working on the ways...., so far I have made a huge improvement. Unless you rework the ways, you pretty much have to live with the backlash at the worst position or loosen things up so much that the saddle does not remain square. When I tightened up my gib where the ways are the closest together... then I found that the backlash, where the ways were wider, went from 0.00x to 0.0xx. Wow! You could even feel the springing of the y-axis crank handle.

I actually found that measuring backlash is the most effective method I have for adjusting the gib.

It is easy to compensate for backlash when cutting straight cuts. The software will not be able to do so on a curve, so I think circles always become ellipses. However, how often are you machining a circle in the plane of the z axis! When I am drilling an array of holes you can easily compensate for backlash by always approaching the next hole from the same directions. This is simple if you are writing your own g-code.

The gear driven head on my 940 is very heavy. I estimated it to be between 250 and 275#s +-. Nod is a something you live with and I think this weight actually bows the distance between the ways (pinches the ways toward each other) in the center position. I am not saying that the column bends over, it is just being collapsed together due to the weighted cantilevered head ... a very small amount showing up as way spacing decrease of a few thousands. This means that the head nods and the gib becomes looser in some positions. So backlash varies with vertical position. The solution to this is to reduce the head weight .. or some how make the column even stronger. Maybe a counter balance of some type. I think the head on the PM728 is significantly lighter and the machine is suppose to be much better made all the way around... so hopefully this is not much of an issue for you.

So, you might want to try to set the gib when you are at the top of the column by monitoring the backlash (setting it to be small) at this position... and then measure it at the bottom to see if it is still small. Of course the nod at the bottom position may increase.

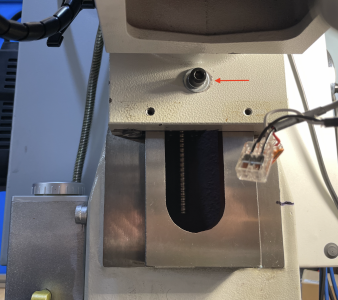

Another thought, check the lead screw alignment. Assuming that the lead screw only has bearings at the motor end (top) then the bottom is free to flex when the ball nut is at that location, but it for some reason the ball nut is not properly aligned at the upper position and the lead screw cannot flex then this tightness can cause a load ... backlash.

Good luck.

Dave L.