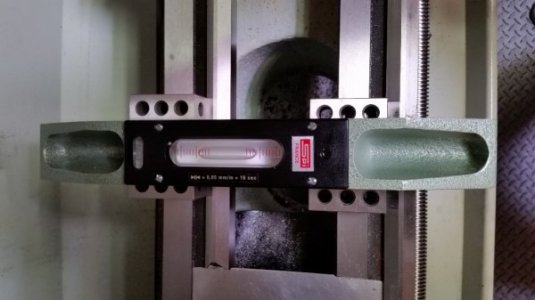

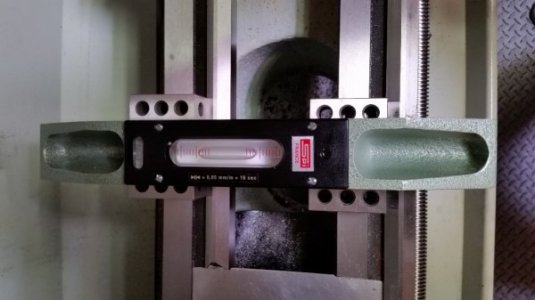

I have seen quite a few of these precision levels show up with a broken wood box, including mine. The boxes are often thin wood on the top and bottom, and the dovetail on mine end was loose. Starrett have better boxes, you pay for it. I think any of the ones described (0.0004 or 5" per foot sensitivity) will work decently to measure bed twist. I prefer an 8", as it is easier to use on most smaller machines. I stand mine off on 123 blocks on the ways, or you can put it on the cross slide (they will not measure the same tilt), but you are looking for bed twist so it is all relative. Although the larger Starrett 199 is popular, it is expensive and too long to go across the ways. The polish ones come up occasionally, and can be very nice, I use an EDA (labeled SPI) that is also very nice. Bottom line, you might use it once every 6 months, no reason to bust the bank on anything fancy.

http://www.ebay.com/itm/Master-Precision-Level-8-Graduation-0-0005-NEW-/311696459034

http://www.ebay.com/itm/SHARS-8-MASTER-PRECISION-LEVEL-FOR-MACHINIST-TOOL-NEW-0005-NEW-/331612008154

I will level the lathe lengthwise first, then adjust check for bed twist. I then check headstock alignment, adjust if needed, and as a last resort you may need to do some minor tweaking for bed twist. I do not consider myself an experienced machinist, but I often see people try to twist the crap out of the bed to get even cutting along a test bar, and often the headstock is out of alignment or it is an issue with the chuck. It can take some time to get everything leveled and aligned, taking your time and doing correctly is worth it in the long run. One last thing, depending on the feet you use and the foundation, the machine level can change, so check it periodically. The precision levels are very sensitive to temperature, they need to stabilize at temperature, always place the level in the same position on the ways, some have a slight hollow ( a few 1/10,000ths) scraped into the center of the base.