-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Practice scraping

- Thread starter vettebob

- Start date

- Joined

- Jul 1, 2012

- Messages

- 1,356

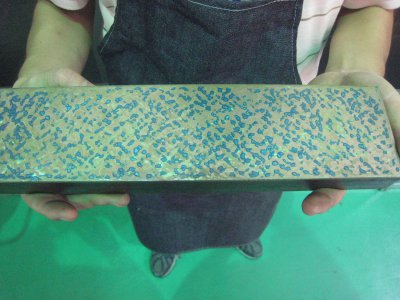

I was hoping some of the other guys would answer first....The short scrapes look good...it looks like your scraping 90 LLL deg to each other try 45 deg xxx. Blue it up and lets see what it looks like. The pic is 40 PPI done with a Biax Scraper. The chart is one I hand out to my students. That is a handy reference when looking at scraping sq inch.

Rich

Rich

Attachments

Last edited by a moderator:

- Joined

- Dec 23, 2012

- Messages

- 25

Some other comments:

- It looks like you are scraping too shallow, but it's hard to tell from a pic. Try sweeping an indicator over it and see how deep the individual scrapes are. You want at least a few tenths deep on an individual scrape mark.

- How flat is it? We need a picture of bluing marks to get an idea. I find it tempting to put pretty finish scraping marks down before getting it flat. It's just wasted effort if I isn't flat. Getting it flat calls for bigger, possibly uglier scraping to get it flat. In fact, ugly scraping can be flat an pretty scraping can be no flat. It doesn't have to be that way, though.

I removed about 15 thou with deep scraping to get a lot of the depressions out then tried to use really small strokes to put a nice finish to it. Tomorrow I'll make a couple more passes rebluing it . (I tore out my rotator cuff and can only do a little at a time). I'll have to get a 0-4-0 dti mine only reads 5 tenths. From reading Rich's comments in another thread I think I over stoned it.

Thanks For the advice Guys I appreciate it. Bob

Thanks For the advice Guys I appreciate it. Bob

- Joined

- Jul 1, 2012

- Messages

- 1,356

I scraped a little more and left the blueing on for the pic. View attachment 58790

Open the PDF at the bottom of my picture on my last post, for some reason it was added under the picture and looks like its part of the picture. It is a chart of % of points and points per inch. We want on average machines or "conventional" which are lathes, mills, surface and centerless grinders we want 40 to 60% (POP) with 20 points per inch (PPI) with an accuracy of .0002" per 12" . On straight edges, surface plates, jig bores, "super precision" machines we want 40 to 60% POP with 40 PPI with an accuracy of .00005" per 12".

You have over stoned it and have the sort of contact we want when we are looking for a static contact bearing on a steam fit 90% to 100% contact. In way bearing we want 50% contact. Think of the word "bearing" a ball bearing has balls or high spots. You have a "bearing" it has high contact points. 50% is a low spot that holds grease or oil as does a ball bearing. The high spots carry the weight and as it moved the thin layer of oil flows over it or lubricates the high spot from the oil low pocket*. If you have ever used gage blocks and "stacked" them.

You rub the flat surfaces of the gage block to "wringing" them together. Friction makes them stick together (wringing; From Henry Ford trade school book "scientists have offered "atmospheric pressure", "molecular attraction" and a "minute film of oil on the lapped surface" is an explanation of this phenomena. Or maybe it's a combination of all three."). The same thing happens on a way when you get a "bearing" like this with so much contact. In machines we call it "stick slip" when you move the way and it has a stutter motion until it either gets enough oil under it or moves smoothly of it, or it rings so perfect together no oil can reach it and the metal erodes and you get scores.

You need to scrape deeper and make a checker board look one low spot, one high spot, etc. the scraped spot should average .0002" deep and we do a final pass called flaking on the unexposed way of the 2 "way system" . The most common is 1/2 mooning flaking, but other builders use a square cut for their "signature" last pass.

* The oil is distributed to the way via an oil pump or reservoir, a oil grove, oil roller, etc.

I hope you understand and this makes sense. Rich

Last edited by a moderator:

- Joined

- Jul 1, 2012

- Messages

- 1,356

The old saying..You learn something everyday Thanks, I have always thought it was spelled without the w. But know I learned something.

I fixed it plus added something extra. Thanks, Rich

I fixed it plus added something extra. Thanks, Rich

- Joined

- Dec 23, 2012

- Messages

- 25

There are at least two ways to remedy the high bearing percentage you have:

I think it's best to rescrape, but it's good to have lots of tricks in your bag. Stoning is mostly used to remove burrs. You only need a few swipes for that.

- Rescrape the area

- scrape small, precise scrape to break up the big spots into more small spots.

I think it's best to rescrape, but it's good to have lots of tricks in your bag. Stoning is mostly used to remove burrs. You only need a few swipes for that.

- Joined

- Aug 23, 2013

- Messages

- 970

What about starting with a surface that has been ground on a surface grinder? I have several machines that really need cleaned up and was thinking that a surface grinder would straighten and flatten out to create a good surface to start with. Tim