I brought this lathe back in 2015, originally as a source of spare parts (change wheels and faceplate and chuck for a smaller Portass PD5 lathe that I was playing with). Having got it back I realised this was a more complete and capable lathe than the PD5 which I sold, but as is so often the case other priorities took over and this lathe languished in my work store and became surplus to requirement when I brought a Colchester Bantam lathe at the end of 2017. For some reason though I've not been able to part with this and felt honour bound to put it back into proper working order before....

The Portass Lathe Company was based in Sheffield, England and manufacturing engineering machinery from the late 1890s to 1970s. There is an excellent history of the company and portass machines on Tony Griffith's excellent site Lathes.co.uk - http://www.lathes.co.uk/portass/

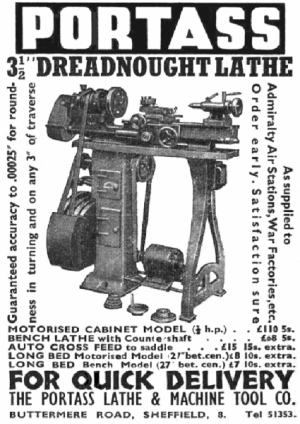

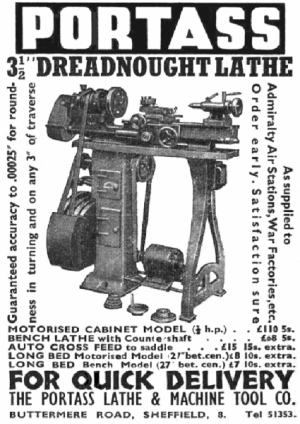

Originally my lathe would have looked like the following sales illustration:

It was broadly comparable with the early Myford ML3 and other flat/gap bed lathes of this vintage.

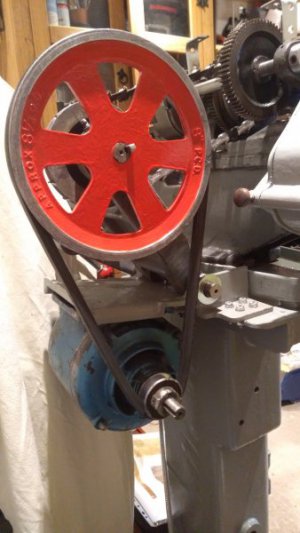

But when I acquired it is was in rather poorer condition and had been converted to vee belt drive. At some point the back gear had been removed to allow a rather botched mounting of counter shaft - it did how come with lots of (rusty) bits and at a bargain price!

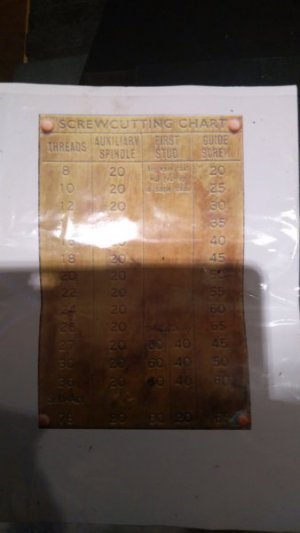

Most of the rusty parts and bed were initially cleaned using reverse electrolysis and the lathe was in pretty reasonable condition other than the standard knocks to the lathe bed at the gap, and I ended up with the full set of change wheels (most showing little or no use).

After 4 years being moved around my store at work, I finally brought the lathe home in January and have slowly got around to cleaning, restoring the back gear shaft and coming up with a new counter shaft arrangement (based on an old Boxford AUD counter shaft that I brought several years ago). I also added a modern NVR switch with Stop Button and rewired the motor and Dewhurst switch so that the motor can be reversed (with care as the chuck is threaded on to the spindle.

Functionally complete, but still a little fettling to finish this off and find a new home so that I can reclaim the workshop space.

The Portass Lathe Company was based in Sheffield, England and manufacturing engineering machinery from the late 1890s to 1970s. There is an excellent history of the company and portass machines on Tony Griffith's excellent site Lathes.co.uk - http://www.lathes.co.uk/portass/

Originally my lathe would have looked like the following sales illustration:

It was broadly comparable with the early Myford ML3 and other flat/gap bed lathes of this vintage.

But when I acquired it is was in rather poorer condition and had been converted to vee belt drive. At some point the back gear had been removed to allow a rather botched mounting of counter shaft - it did how come with lots of (rusty) bits and at a bargain price!

Most of the rusty parts and bed were initially cleaned using reverse electrolysis and the lathe was in pretty reasonable condition other than the standard knocks to the lathe bed at the gap, and I ended up with the full set of change wheels (most showing little or no use).

After 4 years being moved around my store at work, I finally brought the lathe home in January and have slowly got around to cleaning, restoring the back gear shaft and coming up with a new counter shaft arrangement (based on an old Boxford AUD counter shaft that I brought several years ago). I also added a modern NVR switch with Stop Button and rewired the motor and Dewhurst switch so that the motor can be reversed (with care as the chuck is threaded on to the spindle.

Functionally complete, but still a little fettling to finish this off and find a new home so that I can reclaim the workshop space.